For the rest of the book, click here. For more information on the impact-vibration hammers, click here. When carrying out excavation work in winter or in permafrost conditions, the most labor-intensive and expensive operation is the loosening (preliminary destruction) of frozen soil. This operation is performed using various mechanisms and devices. All of them have … Continue reading Application of Vibratory Hammers in the Development of Frozen Soils

Application of Vibratory Hammers for Soil Compaction

For the rest of the book, click here. Vibratory compaction has become an important technique for soil improvement. It is interesting that at the start vibratory pile drivers were used in the early development of the technology. Vibratory pile drivers are increasingly used in industrial and hydraulic construction to compact soils. Currently, there are two … Continue reading Application of Vibratory Hammers for Soil Compaction

Use of Vibratory Hammers for Trenchless Pipe Laying

For the rest of the book click here. Currently, several methods are known for trenchless pipe laying: puncture - pressing closed pipes, punching with simultaneous development and removal of soil from the pipe and horizontal drilling. For trenchless installation of pipes with a diameter of up to 500 mm, used as casings for laying pipelines … Continue reading Use of Vibratory Hammers for Trenchless Pipe Laying

Drilling Using Vibration of Deep Dewatering and Artesian Wells

For the rest of the book click here. Recently, some construction organizations have begun to use the vibration method for immersing and removing large-diameter casing pipes. At Stalingradgidrostroy recently [65], a hydrovibration method for immersing pipes with a diameter of 400-500 mm has been developed and successfully implemented. Using this method, it was possible to … Continue reading Drilling Using Vibration of Deep Dewatering and Artesian Wells

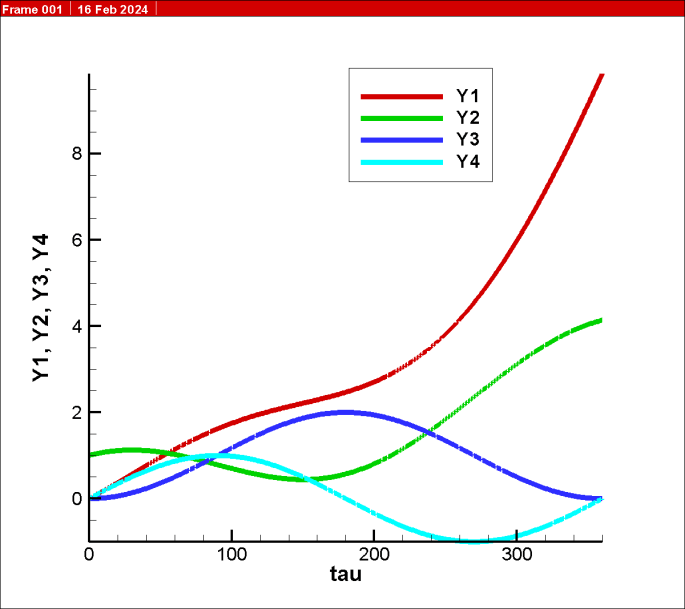

Analysis of Vibratory Pile Drivers using Longitudinal and Rotational Oscillations with a Purely Plastic Soil Model

This is another in a series of technical reports on vibratory and impact-vibration pile driving equipment. It is scheduled to be presented at the 2024 Arts and Research Conference at the University of Tennessee at Chattanooga. You can download the paper here. The abstract is as follows: Abstract: Driving piles by longitudinal vibrations has been … Continue reading Analysis of Vibratory Pile Drivers using Longitudinal and Rotational Oscillations with a Purely Plastic Soil Model

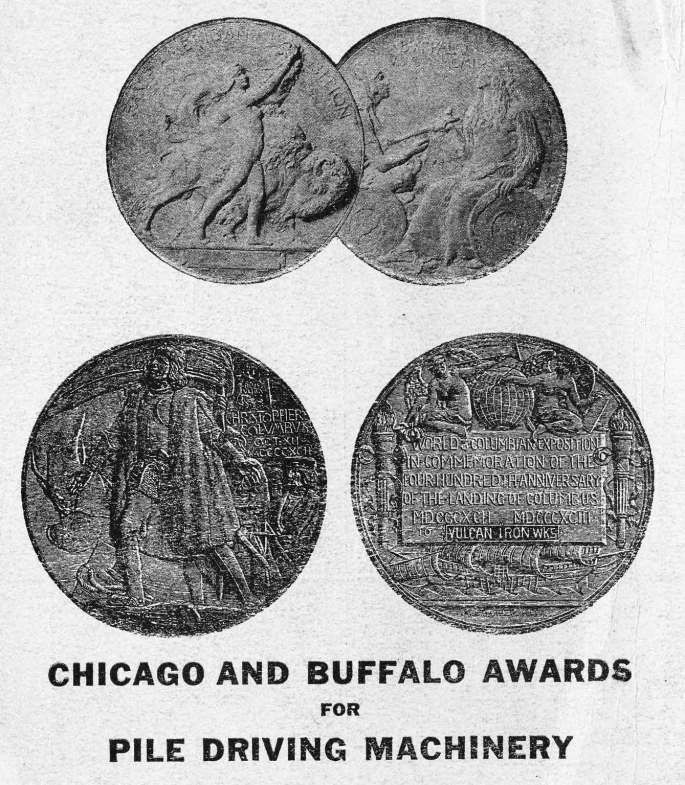

Vulcan’s Awards at the Columbian (Chicago, 1893) and Pan-American Expositions (Buffalo, 1901)

Showing off the product: a diagram of Vulcan's product line exhibition at the Pan-American Exhibition in Buffalo, NY, in 1901. Vulcan participated in most of the "world's fairs" of the era, including the Columbian Exhibition in Chicago. It's worthy of note that all of the products shown here: the leaders, the #2 steam hammer, the … Continue reading Vulcan’s Awards at the Columbian (Chicago, 1893) and Pan-American Expositions (Buffalo, 1901)

Construction of concrete cast-in-place piles and sand piles-drains using the vibration method

The rest of the book is here. Both of these topics would also occupy Vulcan and the construction industry. In the late 1950's and early 1960's Vulcan would develop its Sand-Drain hammers, but as you can see the Soviets were already doing this installation using vibratory drivers. (For an overview of sand drains and Vulcan's … Continue reading Construction of concrete cast-in-place piles and sand piles-drains using the vibration method

Application of Low-Frequency Longitudinal Vibratory Hammers for Immersion of Hollow Piles and Shell Wells into the Ground

For the rest of the book, click here. By "shells," the Russians mean large concrete cylinder piles. Raymond Concrete Pile was developing their own prestressed cylinder piles for work in Venezuela and the Chesapeake Bay Bridge/Tunnel, with diameters up to 66". For their part the Russians were installing working piles up to 1.55 m (61") … Continue reading Application of Low-Frequency Longitudinal Vibratory Hammers for Immersion of Hollow Piles and Shell Wells into the Ground

About the Bearing Capacity of Piles Driven by Vibration

For the entire book, click here. This is something of the "Holy Grail" of the whole vibratory project: the ability to estimate the static capacity of piles driven by vibration. The Soviets took up the question early in the development of these machines and ran into the same obstacles that most everyone since then has … Continue reading About the Bearing Capacity of Piles Driven by Vibration

Production Experience of Driving Heavy Reinforced Concrete Piles with Low-Frequency Longitudinal Vibratory Hammers

For the rest of the book, click here. Driving concrete piles by vibration is still not as accepted as it should be, but doing it has preoccupied researchers both geotechnical and equipment application since the early days of the technology. The Soviet approach to it was to use low speed, high eccentric-moment vibrators, a practice … Continue reading Production Experience of Driving Heavy Reinforced Concrete Piles with Low-Frequency Longitudinal Vibratory Hammers