Goodrich's 1908 study on dynamic formulae was interesting but not as informative as one would like and not as impactful as he might have hoped. Wellington's Engineering News Formula continued to dominate the scene (in the U.S., at least) and other formulae were coming in and out of vogue here and elsewhere. Goodrich had restricted … Continue reading An Industry Gets Restless: Terzaghi’s 1929 Paper on Dynamic Formulae and the Response

Travelling Through History While Seeking a Sale

Recently I watched this video about the Boxer Rebellion in China: https://youtu.be/bkU3kae4mFw Readers of the series A Fistful of Yuan: Vulcan in China, 1981-3 who watch the video will recognise that Vulcan's representatives were in the trail of the Boxer Rebellion in places like Tianjin, Tanggu and Beijing itself. Although the foreign concessions were long gone … Continue reading Travelling Through History While Seeking a Sale

Goodrich (1908): The First Instrumented Pile?

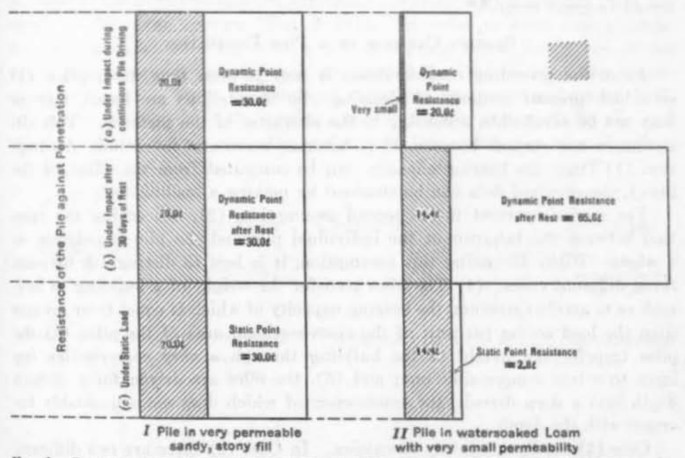

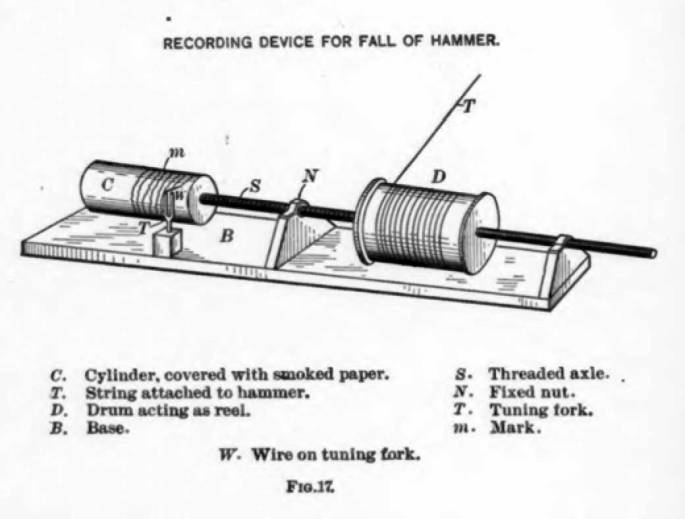

The results of the Proctorsville project showed that our understanding of the mechanics of pile driving—and of the load transfer mechanism between pile and soil during and after installation—left a great deal to be desired. The solution to the problem was to instrument the pile driving process. Such an effort was documented in the 1908 … Continue reading Goodrich (1908): The First Instrumented Pile?

New Year, New Prices: Geotechnical Books Update

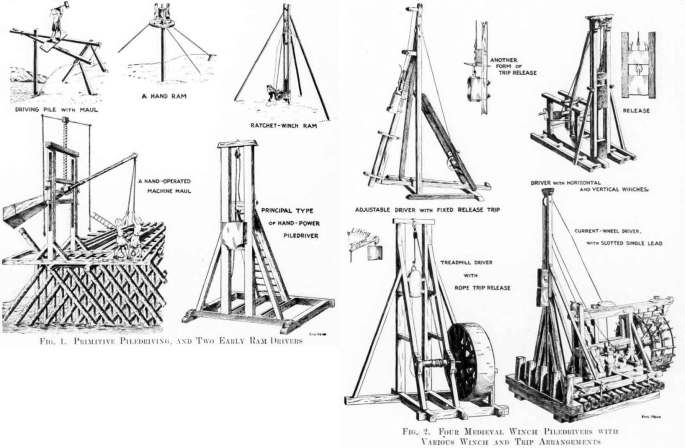

The Source of Those “Primitive Pile Driving” Drawings

Most people in our industry have seen the drawings shown above. They were featured (in much better quality, I must admit) in Chellis' Pile Foundations (1961), which was the book on the subject at the time and for many years afterward. Their source, however, has been something of a mystery, but now that mystery can … Continue reading The Source of Those “Primitive Pile Driving” Drawings

The Vulcan Drawing Cabinet

In its early years and down to about World War II, Vulcan was very much a "vertically integrated" company, including its own foundry and blacksmith for forgings. Sometimes that extended to the furniture itself, and above is a drawing of cabinets for drawings, probably with enough detail for you to build one yourself. Vulcan got … Continue reading The Vulcan Drawing Cabinet

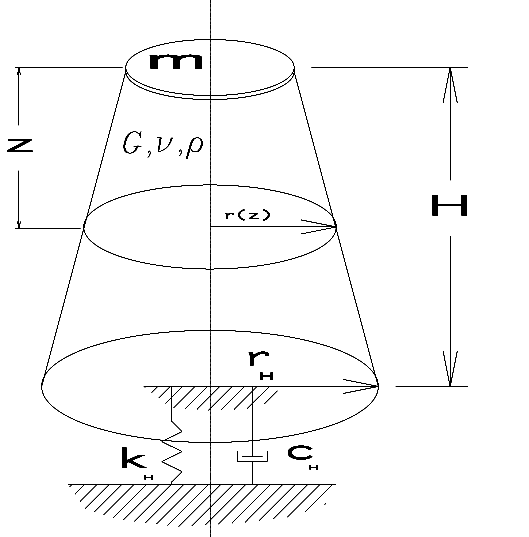

Comments on “Nonlinear fictitious-soil pile model for pile high-strain dynamic analysis” and “Fictitious soil pile model for dynamic analysis of pipe piles under high strain conditions”

It's my custom to review papers which cite my own work. This pair of papers, whose lead author is Tu Yuan from Zhejiang Sci-Tech University in Hangzhou, China, is interesting because it take an approach whose basic concept goes back a long way in pile dynamics and which needed some basic advancement. The two papers … Continue reading Comments on “Nonlinear fictitious-soil pile model for pile high-strain dynamic analysis” and “Fictitious soil pile model for dynamic analysis of pipe piles under high strain conditions”

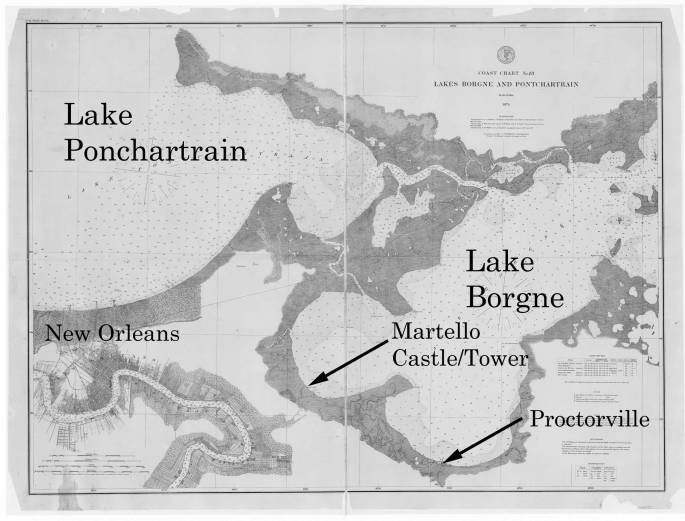

Putting Dynamic Formulae to the Test: the Proctorsville Fort Project

As we saw in the previous post, Sanders' Formula wasn't the last word in dynamic formulae, and neither were Weisbach's. Faced with this proliferation, the U.S. Army Corps of Engineers put together the document Pile Foundations and Pile-Driving Formulae, Circular No. 17, Office of the Chief of Engineers, U.S. Army. It was dated 28 November … Continue reading Putting Dynamic Formulae to the Test: the Proctorsville Fort Project

1923: “Assurances of Continuing Improvement” — AASHO Acquires Both a Trailblazing Leader and Its First Home Base in Washington, D.C.–Transportation History

http://transportationhistory.org/2026/01/02/1923-assurances-of-continuing-improvement-aasho-acquires-both-a-trailblazing-leader-and-its-first-home-base-in-washington-d-c/ While AASHO was settling into its new digs, Vulcan was under absentee (as far as the Warrington family was concerned) leadership. William H. Warrington had died two years earlier, George Warrington was in his last years in Washington, James N. Warrington was living in the Los Angeles area because of his health, and his … Continue reading 1923: “Assurances of Continuing Improvement” — AASHO Acquires Both a Trailblazing Leader and Its First Home Base in Washington, D.C.–Transportation History

GRLWEAP Accessory Specifications for the Vulcan #2 and 30C Hammers

When WEAP86/87 was introduced, one of the major advances was the inclusion of a comprehensive hammer database. This has been continued and expanded in subsequent versions such as GRLWEAP 2003 and GRLWEAP 2010. One anomaly was that, although the Vulcan #2 and Vulcan 30C hammers were included in the database, the driving accessory information was … Continue reading GRLWEAP Accessory Specifications for the Vulcan #2 and 30C Hammers