It is with great regret that the discontinuation of our "active pages" is announced. By "active pages" we mean the software that was designed for use in a web browser. With the migration of the "vulcanhammer" family of sites it is not possible to host these here, and changes in the hosting service have made … Continue reading The Discontinuation of Our Active Pages, and the Substitutes

Category: Uncategorized

Basics Of The Theory Of Vibratory Immersion and Extraction

Click here to view the home page for the book. The theory of vibrational and impact-vibrational immersion is connected with the study of essentially non-linear systems, in which the nonlinearity is determined both by the forces of resistance (for example, when studying longitudinal-rotational vibrations) and by the dynamics of the vibration exciter itself, for example, … Continue reading Basics Of The Theory Of Vibratory Immersion and Extraction

Mounting Pile Hammer Leaders on a Forklift

The development of excavator mast technology has broadened the application of pile driving equipment. Below is another way of mounting pile driving equipment, in this case using a heavy duty forklift. https://youtube.com/shorts/BnbMkty7ZBc?feature=share MKT 10B3 operating on a Manitou MHT 10210 forklift with leaders, headblock and fork mounts put together by Vulcan Foundation Equipment, Ft. Payne, … Continue reading Mounting Pile Hammer Leaders on a Forklift

Making an Impact on Sheet Piling

Although the classic Warrington-Vulcan and Super-Vulcan hammers were not the best suited to interface with sheeting, doing so was very common for these versatile hammers. Here are some examples broken down into two parts: the sheeting layouts and the cap configurations. These are from the years Vulcan was in Chicago, before it moved to Chattanooga … Continue reading Making an Impact on Sheet Piling

Vulcan Never Believed in a “Throwaway Culture”

There's finally some meaningful pushback against this: But significant amounts of that waste could be avoided through repairs. According to a study by the French Environment and Energy Management Agency, only 40% of electronics breakdowns in France are repaired. But surveys have found nearly two-thirds of Europeans would rather repair their products than buy new … Continue reading Vulcan Never Believed in a “Throwaway Culture”

Driving Concrete Piles Wild

Driving piles wild, i.e., without any leader of any kind, is something that takes a great deal of skill and forethought by the contractor. Like piles driven with a stub leader, it is necessary at least to use some kind of template to insure that the pile is on location and in alignment, and also … Continue reading Driving Concrete Piles Wild

Leaving the Derrick Barge Behind

Above is a photo of one of Ingram Construction's barges in the wake (literally) of the crew boat carrying Vulcan's representative (probably Jess Perry) away after a field service trip. Vulcan developed its field service capabilities mostly in response to its customers in the Gulf of Mexico and elsewhere, and that frequently entailed long field … Continue reading Leaving the Derrick Barge Behind

Chabahar: a Vulcan “Almost” Becomes a Point of Contention with the Suez Canal

The Iranians want to bypass the Suez Canal using their port at Chabahar: The Iranian Chabahar Free Trade Zone Organization announced July 5 that trade connections to Mumbai, Hamburg and St. Petersburg will be made through Astrakhan (in Russia), Anzali and Chabahar (in Iran) and Nhava Sheva (in India) instead of the Suez Canal. This raises questions … Continue reading Chabahar: a Vulcan “Almost” Becomes a Point of Contention with the Suez Canal

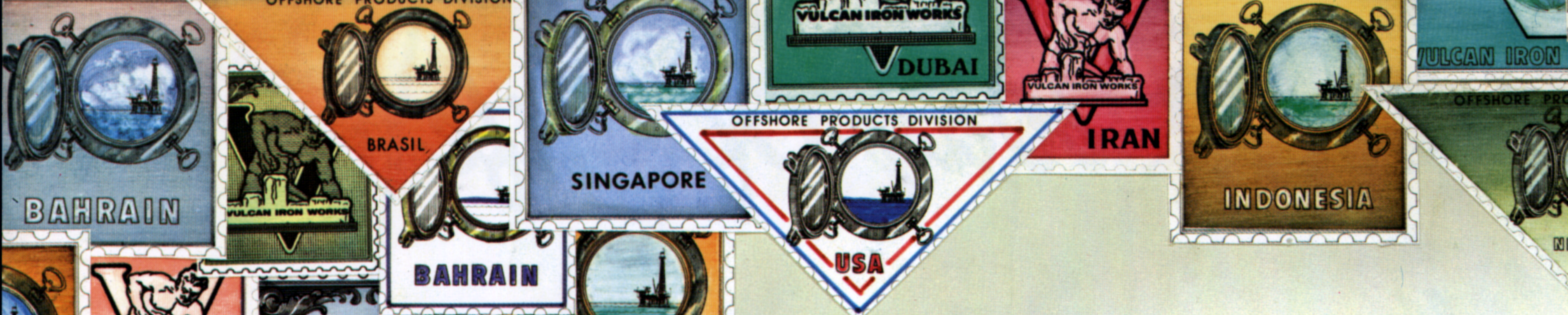

“Offshore pile driving is a high-risk activity as delays can be financially punitive”

I've had experience on both the practical and "academic" sides of offshore pile driving and installation, but I've seldom seen a blunter and more accurate summary of the topic in the published literature than what's above. Vulcan certainly experienced that during the offshore years. The entire paper can be obtained here. The complete abstract is … Continue reading “Offshore pile driving is a high-risk activity as delays can be financially punitive”

Vulcan 060 and 360 Hammers: Specifications and Information

The success of the 040 was soon left behind by the deeper and deeper water conventional platforms were being installed into. That in turn called for larger hammers, and Vulcan rose to the occasion with the 060. The first 060 was built for J. Ray McDermott and delivered in the summer of 1968, a summer … Continue reading Vulcan 060 and 360 Hammers: Specifications and Information