Sheet pile walls are deceptively simple retaining walls to analyse. Because a) the loads are generally distributed and b) the layering of the soil is complex, a simple problem can turn into a complicated one very rapidly. An outline of the hand solution method for cantilever walls is shown below. That's why today software such … Continue reading Designing Cantilever Sheet Pile Walls Using a Chart

Author: Don Warrington

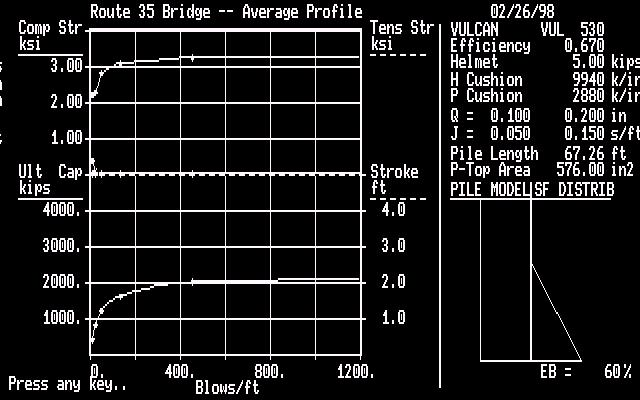

The Wave Equation after TAMWAVE: Alternatives and Substitutes

The discontinuation of the TAMWAVE wave equation program has left something of a void in our offerings. This post explores the alternatives that we have on hand, primarily for educational purposes. (All offerings of this site are subject to the Terms and Conditions of This Site.) The Problems When the first geotechnical site of this family … Continue reading The Wave Equation after TAMWAVE: Alternatives and Substitutes

The Discontinuation of Our Active Pages, and the Substitutes

It is with great regret that the discontinuation of our "active pages" is announced. By "active pages" we mean the software that was designed for use in a web browser. With the migration of the "vulcanhammer" family of sites it is not possible to host these here, and changes in the hosting service have made … Continue reading The Discontinuation of Our Active Pages, and the Substitutes

“Analysis of Vibratory Pile Drivers using Longitudinal and Rotational Oscillations with a Purely Plastic Soil Model” Presentation Now Available

This paper is scheduled to be presented today at the Spring Research and Arts Conference at the University of Tennessee at Chattanooga. The presentation slides for this paper (with its abstract) can be found here. The paper itself is here.

Some Lessons from “Savinov and Luskin”

One of the mysteries of geotechnical engineering relative to driven piles is why the Soviets, with their mathematical prowess, never applied wave mechanics to predict the performance of pile driving systems using the wave equation. In a sense this book, which is a classic in the geotechnical literature, answers that, but not in a direct … Continue reading Some Lessons from “Savinov and Luskin”

References

For the rest of the book, click here. I debated whether to translate the reference section. I ended up deciding not to do so. Most all of the material referenced in this book is in Russian and my guess is that most of it has never been translated into another language. So what I have … Continue reading References

Conclusion

For the rest of the book, click here. The resolution of the June plenum of the CPSU Central Committee emphasizes the need, when developing and implementing new technological processes and machines, to proceed from the point that they meet the requirements of the most rational and economical use of social labor, material and monetary resources, … Continue reading Conclusion

Immersion of Thin Steel Pipes into the Ground

In construction practice, it is sometimes necessary to immerse thin steel pipes into the ground, used as electrodes, piezometers, injectors for cementation or chemical consolidation of soils, etc. With a short pipe length of up to 5-8 m, this operation does not present any great difficulties and is performed manually by driving. As the length … Continue reading Immersion of Thin Steel Pipes into the Ground

Application of Vibratory Hammers in the Development of Frozen Soils

For the rest of the book, click here. For more information on the impact-vibration hammers, click here. When carrying out excavation work in winter or in permafrost conditions, the most labor-intensive and expensive operation is the loosening (preliminary destruction) of frozen soil. This operation is performed using various mechanisms and devices. All of them have … Continue reading Application of Vibratory Hammers in the Development of Frozen Soils

Application of Vibratory Hammers for Soil Compaction

For the rest of the book, click here. Vibratory compaction has become an important technique for soil improvement. It is interesting that at the start vibratory pile drivers were used in the early development of the technology. Vibratory pile drivers are increasingly used in industrial and hydraulic construction to compact soils. Currently, there are two … Continue reading Application of Vibratory Hammers for Soil Compaction