For many years the main method of drivability/resistance correlation were the dynamic formulae. It’s interesting that the Engineering News formula and the Vulcan #1 hammer came into the world at about the same time. Vulcan featured the Engineering News formula in its literature as early as 1906, and this continued until the 1970’s.

For many years the main method of drivability/resistance correlation were the dynamic formulae. It’s interesting that the Engineering News formula and the Vulcan #1 hammer came into the world at about the same time. Vulcan featured the Engineering News formula in its literature as early as 1906, and this continued until the 1970’s.

We explore various topics regarding these, including the following:

- Before Wellington and ENR: Early Dynamic Formulae, and Sanders’ Formula

- The Engineering News Formula, and Its Treatment in Early Vulcan Literature

The dynamic formulae first made driven piles tested piles, as the resistance of the pile could be estimated by the blow count of the hammer, which is readily monitored during driving. The Engineering News formula had the additional advantage that only the hammer’s rated striking energy and the blow count are necessary to make an estimate of the pile’s resistance.

Although the limitations of the dynamic formulae were recognised by Vulcan (if not by some engineers,) for many years they were the accepted method of correlating resistance to hammer performance. Some specifications–especially for timber piles–still call for the Engineering News or other dynamic formulae.

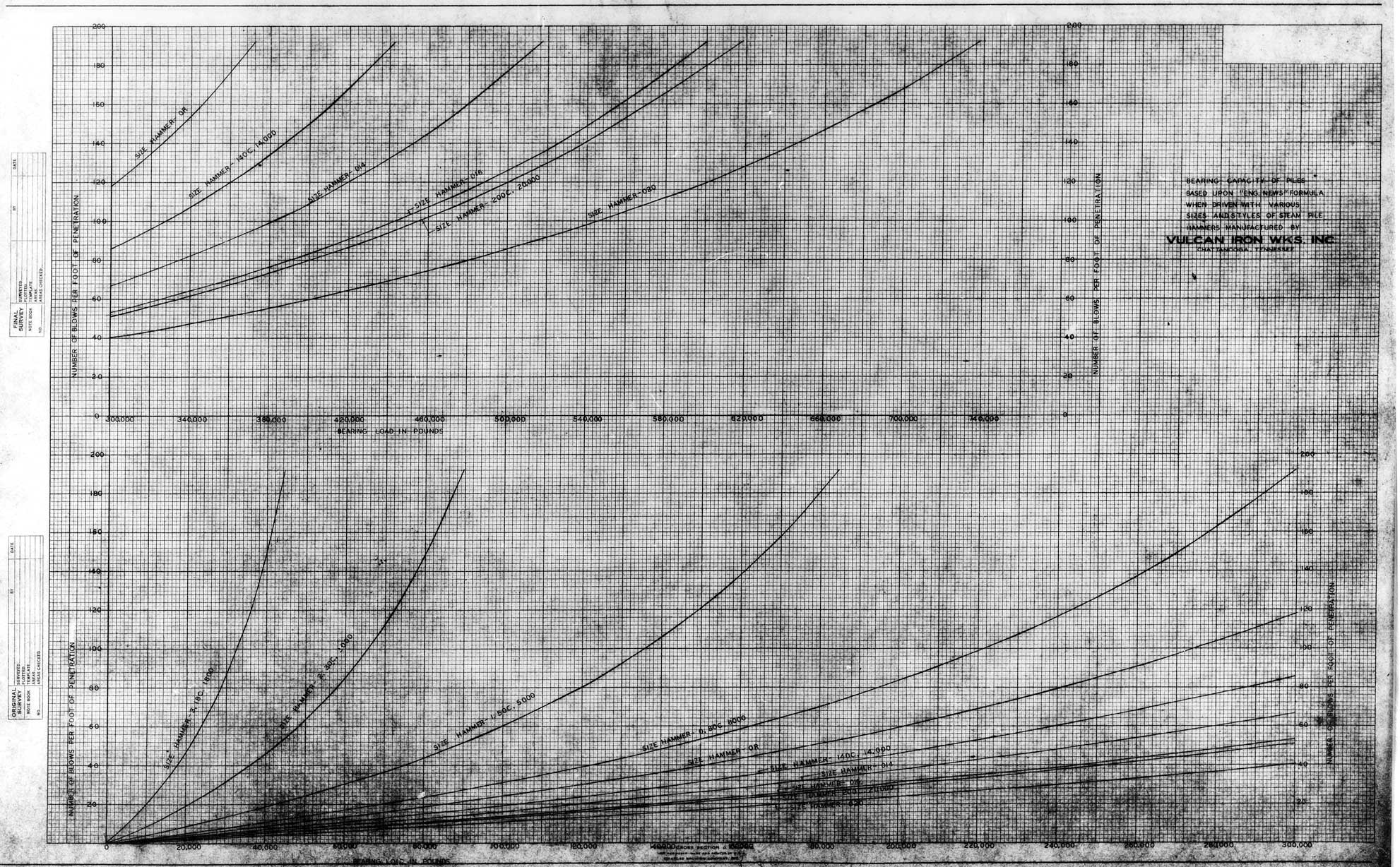

Vulcan included charts in its literature based on the Engineering News formula; an example of a Vulcan EN formula chart is shown above. Information the Gates Formula–which the FHWA recommends as its preferred dynamic formula–can be found in the vulcanhammer.info Guide to Pile Driving Equipment.

Other Monographs on Dynamic Formulae

Design of Timber Foundation Piling for Highway Bridges and Other Structures

James S. Graham

Ritter, Micheal A.; Duwadi, Sheila Rimal; Lee, Paula D.Hilbrich, eds. 1996. National Conference on Wood Transportation Structures. Gen. Tech. Rep. FPL-GTR-94. Madison, WI: U.S. Department of Agriculture, Forest Service, Forest Products Laboratory. 494 p.

Presented information on structures supported by treated timber piling, including details of the East Side (FDR) Drive in New York City. Determined the average and mean Factor of Safety of the Engineering News Formula for 43 site-specific cases. Showed examples of present-day design for timber piling supported by friction, end bearing, or a combination of both. Considered practical and theoretical geotechnical design criteria. Furnished timber piling and preservative specifications. Reviewed durability for foundation, fresh water, and marine piling. Addressed environmental considerations. Concluded that local Geotechnical engineers apply empirical experience to design treated round timber foundation piling.

Development of the WSDOT Pile Driving Formula and Its Calibration for Load and Resistance Factor Design (LRFD)

Tony M. Allen

Washington State Transportation Center (TRAC)

WA-RD 610.1

March 2005

Prior to 1997, WSDOT used the Engineering News Record (ENR) Formula for driving piling to the design capacity. Washington State Department of Transportation (WSDOT) sponsored research published in 1988 had shown that the ENR formula was quite inaccurate, and that moving toward the Gates Formula would be a substantial improvement (Fragaszy et al. 1988). Hence, in 1996, an in-house study was initiated to update the driving formula used for pile driving acceptance in the WSDOT Standard Specifications. Recently compiled databases of pile load test results were used as the basis for developing improvements to the Gates Formula to improve pile bearing resistance prediction accuracy. From this empirical analysis, the WSDOT driving formula was derived. Once the WSDOT driving formula had been developed, the empirical data used for its development were also used to establish statistical parameters that could be used in reliability analyses to determine resistance factors for load and resistance factor design (LRFD). The Monte Carlo method was used to perform the reliability analyses. Other methods of pile resistance prediction were also analyzed, and resistance factors were developed for those methods as well. Of the driving formulae evaluated, the WSDOT formula produced the most efficient result, with a resistance factor of 0.55 to 0.60. A resistance factor of 0.55 is recommended. Dynamic measurement during pile driving using the pile driving analyzer (PDA), combined with signal matching analysis (e.g., CAPWAP), produced the most efficient result of all the pile resistance prediction methods, with a resistance factor of 0.70 to 0.80.

Determining Pile Bearing Capacity by Some Means Other Than the Engineering News Formula

Kenneth L McManis, Michael D. Folse and Janet S. Elias

University of New Orleans/Louisiana Department of Transportation

FHWA/LA-89/234

December 1989

A review of the practice used in monitoring pile driving activities within the Louisiana Department of Transportation and Development (LADOTD) and elsewhere is reported. The Engineering News Record formula is currently the most commonly reported method used by departments of transportation in the evaluation of pile driving. The performance of several alternate dynamic formulas, the wave equation, and dynamic testing with the pile driving analyzer are evaluated in a comparative study of LADOTD test piles. Development of a comprehensive program that includes dynamic formulas but has the goal of greater reliance on the wave equation, from design through construction, is recommended. Microcomputer software was developed to facilitate field implementation of WEAP87, the Hiley and Engineering News Record formulas. In a test pile study, the pile driving analyzer was found to be reliable in predicting pile capacity, monitoring the structural integrity of the pile driving and in evaluating setup.

Improving Agreement Between Static Method and Dynamic Formula for Driven Cast-In-Place Piles in Wisconsin

James H. Long, PhD, P.E.

University of Illinois Urbana-Champaign

WisDOT ID no. 0092-10-09

June 2013

Many transportation facility structures in Wisconsin are founded on driven piling. Round, closed-end, steel, pipe piles are commonly used as friction piles in many structures including bridges and retaining walls. These cast-in-place (CIP) piles have shell thicknesses typically ranging from 0.219 – 0.375 inches and diameters ranging from 10.75 – 16 inches. The piles are driven to capacity and then filled with concrete. Wisconsin DOT’s experience indicates that design pile length estimations have generally been fairly accurate when compared to driven pile lengths. Driven lengths have been determined based on penetration resistance measured in the field using the Wisconsin-modified Engineering News (EN) driving formula, as described in Section 508 of the Standard Specifications for Highway and Structure Construction. However, the Wisconsin Department of Transportation (Wisconsin DOT) no longer uses the EN formula nor the LFD design methodologies and now designs structural transportation facilities using AASHTO Load and Resistance Factor Design (LRFD) methodologies and the FHWA-modified Gates formula. This study focuses on comparing the capacities and lengths of piling necessary as determined with a static method and with a dynamic formula. Pile capacities and their required lengths are determined two ways: 1) using a design and compute method, such as the static method (Nordlund/Thurman/Tomlinson) identified in the Wisconsin Bridge Manual, and 2) using as-driven information, such as the Wisconsin-modified Engineering News Formula, the modified-Gates method, and WEAP.

Pile Driving Formulas for Friction Piles in Sand

Roy E. Olson and Kaare Flaate

In this investigation, seven different pile-driving formulas were used to predict the capacity of timber, concrete and steel friction piles. A linear relationship was assumed between the measured and computed pile capacities, and the reduced major-axis type of linear regression analysis was used to determine the slope and intercept of the regression line. Correction coefficients were used as measures of the scatter about the regression lines. The statistical data were then used to adjust the formulas to improve their accuracy. Conclusions were then drawn regarding the accuracy of the various formulas.

3 thoughts on “Vulcan and Dynamic Formulae”