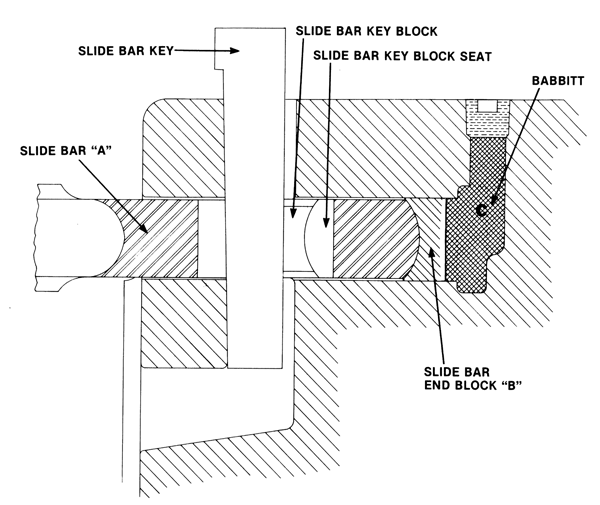

Remove Ram Pipe Plug. Remove old Babbitt by melting with torch. Position Slide Bar "A" and Slide Bar End Block "B" with respect to Ram boss area. (See Tip No. 2) Pour molten Babbitt into cavity at "C" until the Babbitt is 3/4" from the outer surface of the Ram. Reinstall Ram Pipe Plug after … Continue reading Vulcan Onshore Tip #22: Replacing Slide Bar Babbitt

Category: Vulcan Onshore Tips

Vulcan Onshore Tip #21: Slide Bar Shim

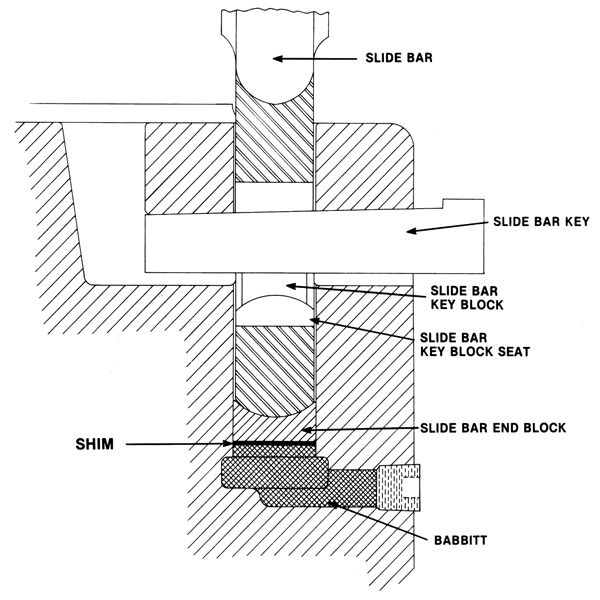

When checking the position of the Slide Bar (as shown in Vulcan Tip No. 2) if you find it below the correct position, add the Shim BELOW THE SLIDE BAR END BLOCK, as shown above. Shims installed under the Slide Bar, for obvious reasons, will create problems.

Vulcan Onshore Tip #20: Extractor Bumper Conversion

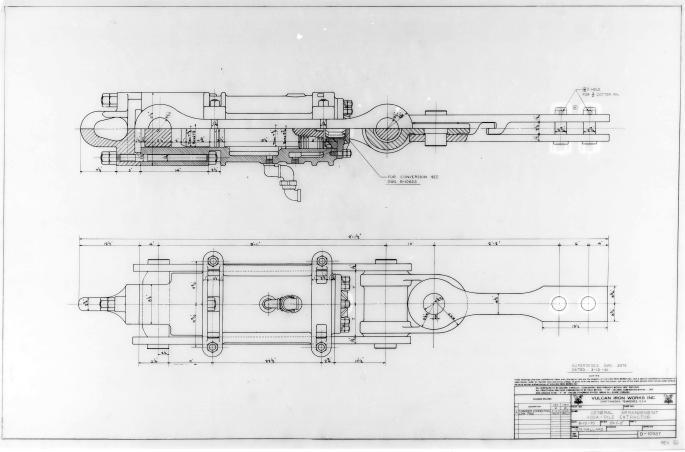

Until recent years Vulcan Pile Extractors utilized a Steel Spring and Spring Guide in the Cylinder head as shown below: To convert older Extractors to the new configuration which replaces the Spring and Spring Guide with a Rubber Bumper the procedure is as follows: Drill through at "A" 1 1/2" diameter. Remove Spring Guide and … Continue reading Vulcan Onshore Tip #20: Extractor Bumper Conversion

Vulcan Onshore Tip #19: Valve Liner

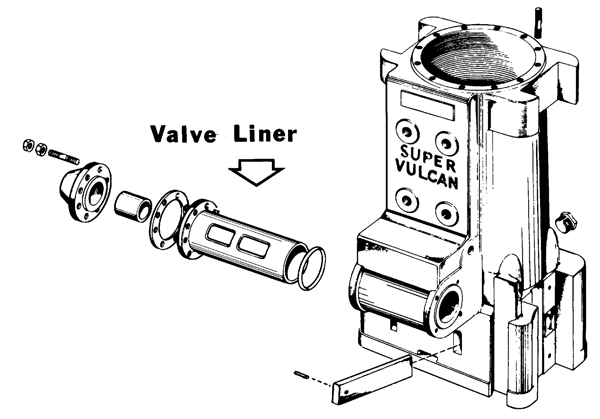

All Hammers shipped from the factory now are equipped with a Valve Liner. When the Valve Seat area is worn the Valve Liner can easily and quickly be replaced. This eliminates the old time consuming and expensive remachining of the Valve Seat. The Liner also allows Valve timing in the field with field tools and … Continue reading Vulcan Onshore Tip #19: Valve Liner

Vulcan Onshore Tip #18: Ram Key Adjustment

After a Hammer has a lot of "mileage" the parts that hold the Piston Rod to the Ram wear a little. This will necessitate some adjustment to insure proper tension of the Ram Keys. If this condition exists in your Hammer and the Ram Keys have a tendency to drive through too far, add Shims … Continue reading Vulcan Onshore Tip #18: Ram Key Adjustment

Vulcan Onshore Tip #16: Piping Do’s and Don’ts

The length of the Nipple from the Inlet must be kept to a minimum. A long Nipple, as shown in the drawing, even though supported by chain or wire rope, will cause damaging leverage and vibration. Extensions to the side, like the arrangement in the picture, allow for good support of the Piping and Hose. … Continue reading Vulcan Onshore Tip #16: Piping Do’s and Don’ts

Vulcan Onshore Tips #15: Base Column Keys

Loose Column Keys can shorten the life of a Hammer considerably. When the Base Keys are loose the Hammer is subject to misalignment and breakage. Loose Keys will slip into the center of the Base and be struck by the Ram Point, breaking the Base. The above drawing shows a quick and easy way to … Continue reading Vulcan Onshore Tips #15: Base Column Keys

Vulcan Onshore Tip #14: Vulcan Extractors

Note: background information about Vulcan extractors can be found here.

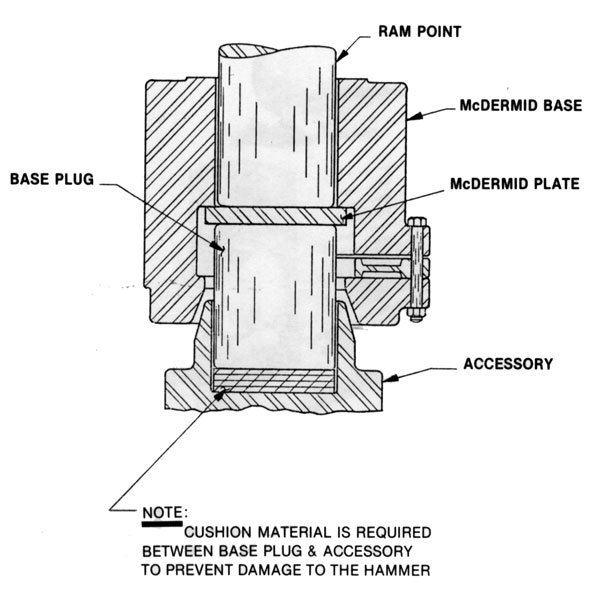

Vulcan Onshore Tip #13: Adaptation of McDermid Base

We do not recommend the use of McDermid base for any type of pile other than wood. But on occasion, contractors have found themselves in a position whom they have had to adapt a McDermid base to standard Driving Heads or Pipe Caps. The above shows the arrangement necessary to accomplish this. Note: the McDermid … Continue reading Vulcan Onshore Tip #13: Adaptation of McDermid Base

Vulcan Onshore Tip #11: Storage

Sometimes contractors forget that a Pile Driving Hammer is a machine and should be treated as such. Especially when the Hammer is to be stored for any length of time. Rust can create havoc in a Hammer. Sometimes the contractor takes a Hammer off of a job and lays it down in the yard expecting … Continue reading Vulcan Onshore Tip #11: Storage