To download the book, click here About the Book All machines are built up of parts made of different materials and by various manufacturing processes. Some parts are cast from metals; some are forged, while others are produced by machining on different kinds of machine tools. Castings and forgings have to be machined before they … Continue reading Forging Practice – Kamenshchikov, Koltun, Naumov, Chernobrovkin

Category: The Products

Maintenance Manual for Super-Vulcan Hammers

The Super-Vulcan hammers were a step forward for Vulcan, albeit not as much as Vulcan was hoping for. Nevertheless they were a popular hammer for many years, especially once Vulcan went to the open type construction like the Warrington-Vulcan single-acting hammers. Here we feature a maintenance manual for these hammers. The manual is undated (an … Continue reading Maintenance Manual for Super-Vulcan Hammers

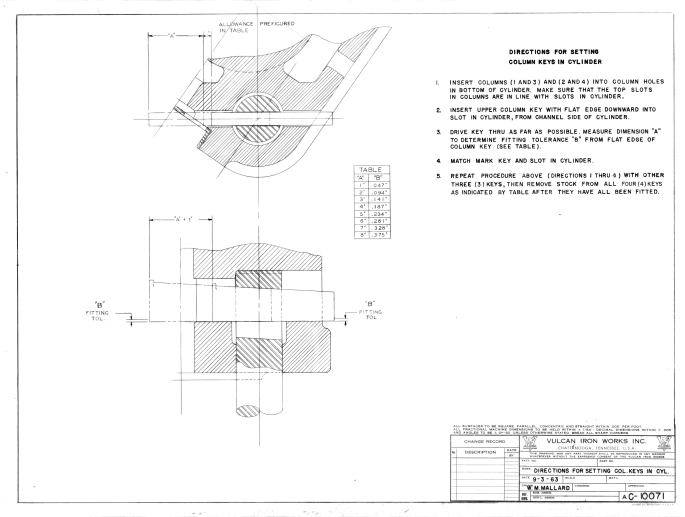

Setting Column Keys in Cylinder and Base

I would think that most Vulcan hammers in operation today are held together with cables. For those that aren't, here is Vulcan's procedure to set cylinder (above) and base (below) column keys, from 1963.

Foundry Practice – Titov, Stepanov

This book is available in print; click here to order About the Book The book is based on the lectures read to the students of machine- building secondary schools and also on the foundry practice course included in the curriculum of the Bauman Higher Technical School of Moscow. The book opens with a detailed description … Continue reading Foundry Practice – Titov, Stepanov

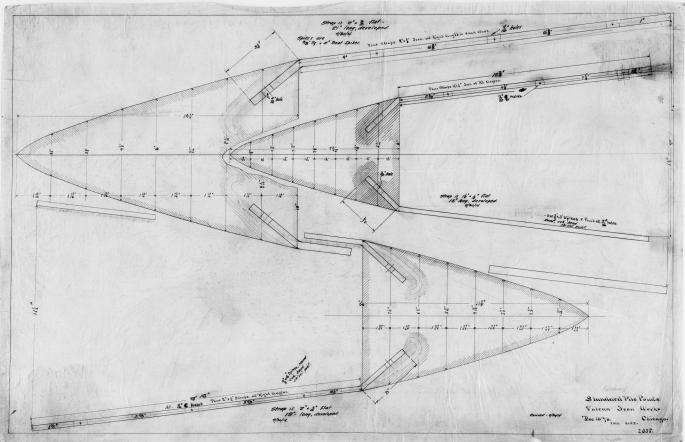

Getting the Point: Vulcan and Pile Shoes

In some ways Vulcan came into the pile hammer business as a "one-stop shop." One of those stops was pile points. The first drawing produced of these was in 1896; the first documented appearance of these accessories in the catalogue was in 1909. As the drawings below show, evidence of them persists until the 1950's.

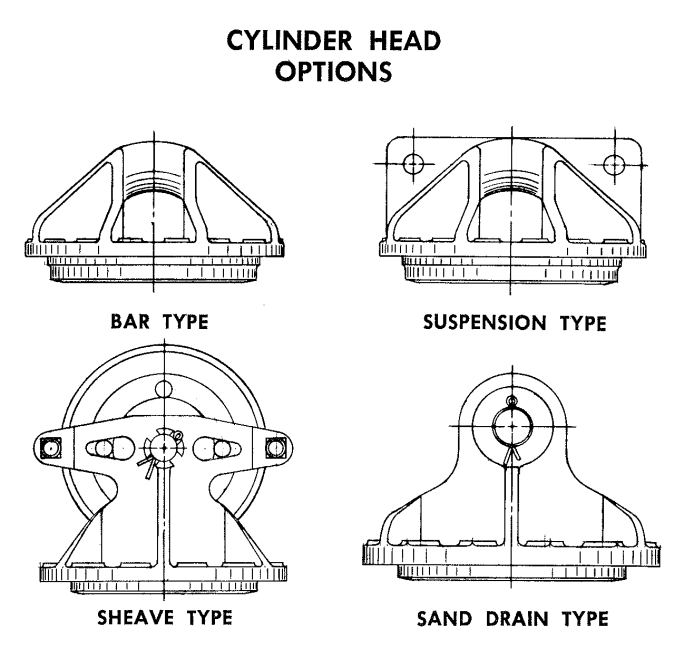

If You’re Not Going to Use a Head Sheave, Use a Bar or Suspension Type Head

In Vulcan Onshore Tip 65, the safe use of sheave type cylinder heads is discussed. A view of the different types of sheave/sheave head/sheave pin/retaining pins from that tip are shown at the right. In the a more recent post, a more detailed diagram of a sheave head is shown below. Some Vulcan users feel … Continue reading If You’re Not Going to Use a Head Sheave, Use a Bar or Suspension Type Head

A Nice Vulcan Hammer Model From One of its Users

Models of Vulcan hammers--working or otherwise--are rare. This one comes from the Boston area, made by one of the pile drivers who worked the Boston waterfront. It is a real gem; I have not seen one this good in a long time. The "front" view of the hammer model. Traditionally Vulcan hammers were run with … Continue reading A Nice Vulcan Hammer Model From One of its Users

Vulcan’s Sight Feed Line Oilers

Proper lubrication is essential to just about any type of moving machinery, and Vulcan's pile drivers are no exception. The most important single point of lubrication is the steam or air cylinder which pulls up (and with some hammers pushes down) the cylinder. Failure to do this will result in reduced efficiency and expensive repairs, … Continue reading Vulcan’s Sight Feed Line Oilers

Raymond 60X Hammer

Raymond Concrete Pile Company (later Raymond International) was in its day the greatest pile driving organisation in the world. It either developed or perfected many of the techniques which are standard for designing and installing driven piles today. The most significant of these was the wave equation, the brainchild of Raymond's chief mechanical engineer, E.A.L. … Continue reading Raymond 60X Hammer

Driving Steel Piles Wild

A few months back we posted Driving Concrete Piles Wild, which documented a Vulcan 020 being used on a project to drive concrete cylinder piles wild. Below is a video of a Vulcan 016 driving steel piles wild: https://youtu.be/t4Zh5ZaeVgc Vulcan 016 driving a steel pile pile wild. Contractor is J.E. Borries; video courtesy of Pile Hammer … Continue reading Driving Steel Piles Wild