For the rest of the book, click here. The main distinguishing feature of the simplest type of vibrodriver (Figure 27) is that all its parts are connected to each other and to the submerged body into one common whole. The vibrator consists of an electric motor 1, a directional vibrator 2 and a head 3; … Continue reading Vibrators of the Simplest Type

Category: A Fistful of Yuan: Vulcan in China, 1981-3

Hard Currency, Soft Currency and Dollar Hegemony

In its dealings with first the Chinese and later with the Soviets, one of the first things Vulcan learned was the difference between hard and soft currency. That was true both in the travel expenses and in the process of selling equipment (and later buying equipment and technology.) Let's start with the Chinese: this notice … Continue reading Hard Currency, Soft Currency and Dollar Hegemony

Forty Years of “A Fistful of Yuan”

My trip report to the rest of Vulcan after I got back from this epic started with the following, forty years ago today: Out of the shadows came Jesse Perry (seated) and Lloyd Berwald. Jesse was Vulcan's most experienced field service person, who also had good customer relations skills along with an extensive knowledge of … Continue reading Forty Years of “A Fistful of Yuan”

Oil and gas fueling South China Sea tensions

Vietnam’s crucial offshore energy industry is being squeezed as US-China tensions rise in the South China Sea. According to reports, China is pressing for the termination of a Vietnamese offs… Source: Oil and gas fueling South China Sea tensions

China’s Historic Houston Consulate Gets the Boot, Goes Up in Flames

In the midst of the souring relationship between the two countries: Beijing vowed to retaliate after it said that the United States ordered its Houston consulate to be closed within 72 hours, calling it an “outrageous and unjustified move,” marking a serious escalation in the quickly deteriorating relationship between the U.S. and China... The announcement … Continue reading China’s Historic Houston Consulate Gets the Boot, Goes Up in Flames

Aboard the Giant Sand-Sucking Ships That China Uses to Reshape the World

From this: As steam power gave way to diesel in the late 19th century, the size and power of dredges grew. Developers in Los Angeles used centrifugal pumps to expand the city’s port and turn marshlands into seaside real estate. Sediment dredged from underwater built Boston’s Back Bay, as well as large portions of Marseilles, … Continue reading Aboard the Giant Sand-Sucking Ships That China Uses to Reshape the World

Riding High in Beijing

During Vulcan's first visit to Beijing in 1981, we saw many vehicles on the road we had never seen before. One of them was the Hongqi (Red Flag) limousine. The one above was parked in front of the Beijing Hotel, where we were staying. Jay Leno's Garage featured one back in 2016; here's the video … Continue reading Riding High in Beijing

A True Russo-Chinese Alliance is Probably Premature

Amidst all of the conventional wisdom about a tight relationship between Moscow and Beijing, a caution: Fifty years later, the ferocity of the skirmish between Mao Zedong’s China and Leonid Brezhnev’s Soviet Union seems to belong to a very distant past—so distant, indeed, that many foreign-policy experts are convinced that an anti-U.S. alliance between the … Continue reading A True Russo-Chinese Alliance is Probably Premature

An Old Idea Comes Back: China-US Arbitration in a Neutral Country

In his assessment of the prospects of US-China relations, former Australian Prime Minister Kevin Rudd makes the following suggestion to resolve intellectual property (IP) issues: Intellectual-property protection, however, is deeply problematic. Previous agreements reached under US president Barack Obama’s administration could be reconstituted. But the jurisdictional enforcement of breaches is still hopeless. One possible mechanism … Continue reading An Old Idea Comes Back: China-US Arbitration in a Neutral Country

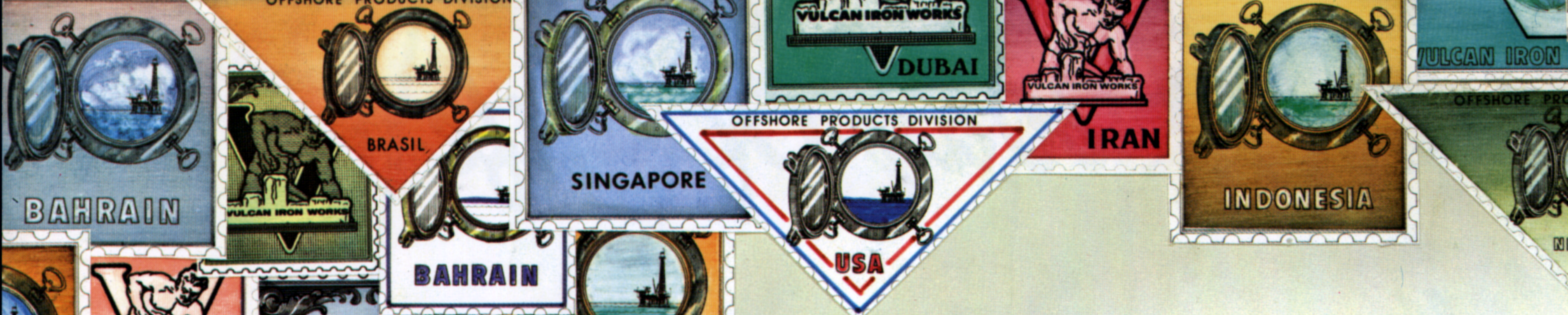

A Fistful of Yuan: Vulcan in China, 1981-3

Readers of the series Vulcan: The Offshore Experience may recall that Vulcan Iron Works' years offshore were described as “the experience of a lifetime.” If there is one experience that stands out as making it that way, it was without a doubt Vulcan's sale of two large offshore pile hammers to the entity that is … Continue reading A Fistful of Yuan: Vulcan in China, 1981-3