Much of the narrative around Vulcan centres on the development of the Warrington-Vulcan pile hammer design in the late 1880’s (and the serial number records aren’t the most informative about when exactly the final transition to that design was made.) But how did Vulcan come up with the valve design it made its standard?

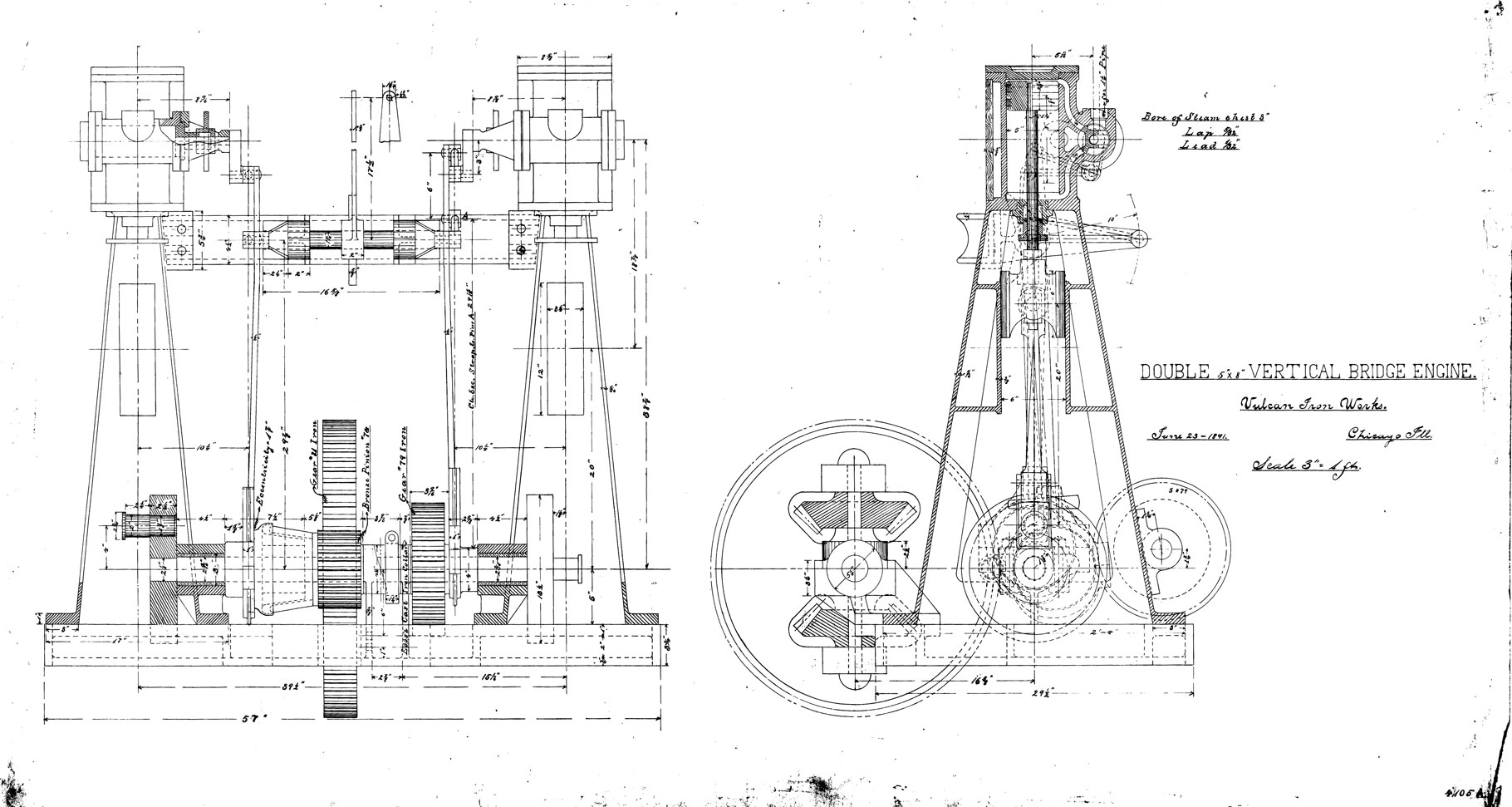

Some clue to that can be seen in the drawing above. It’s a two-cylinder steam engine for a bridge, usually a swing bridge but sometimes a bascule bridge. More information about Vulcan’s bridge related produces is here but it was a significant part of Vulcan’s business in the 1880’s and 1890’s; the design above dates from 1891.

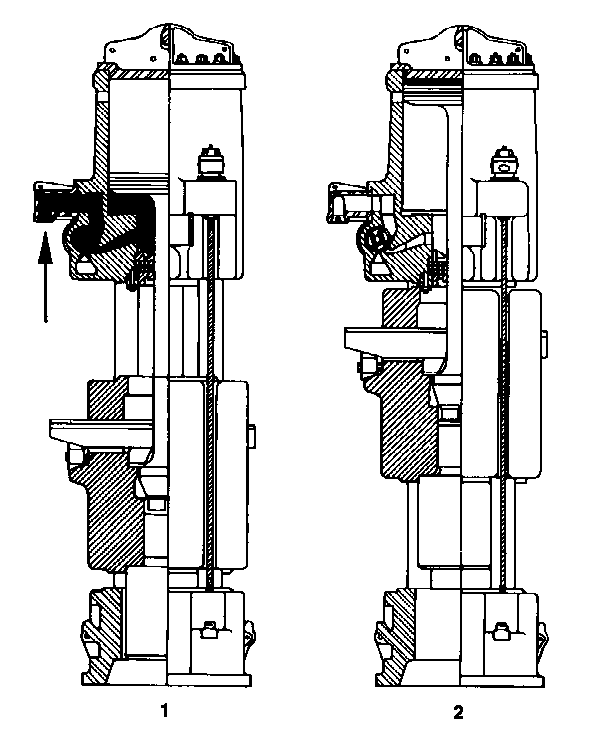

The distinct feature of the above design is the Corliss rotary valve, named after its inventor, George Henry Corliss. Corliss was also instrumental in developing the vertical steam engine, of which the above engine is yet another example. The Corliss valve was best suited for low (< 160 psig) steam pressures and saturated steam (superheated steam at any pressure was rare with Vulcan hammers.) The similarity with Vulcan’s pile hammer valve can be seen in the diagram to the right.

The Corliss valve in the engine at the top had one other important feature in common with its pile hammer successors: mechanical actuation. This made the valve motion more consistent and robust in the impactive environment of pile driving, which was a key to the success of the Warrington-Vulcan hammer.

Another feature of the steam engine is the key used to tighten the connecting rod. Vulcan’s long-use of keys and how they work is discussed here.

As for Corliss, the following inscription was placed on his grave:

Serving God in his life and with his wealth, serving men with a kindness that was both careful and generous. By the gift of God he increased magnificently as an inventor the world’s resources in the use of steam machinery.

2 thoughts on “Some Insight into the Origin of Vulcan’s Pile Hammer Valve System”