Now we get into a topic that’s potentially controversial: the energy rating of diesel hammers, or any impact hammer for that matter. Let’s start with defining what we mean by rated energy.

Efficiency and Rated Striking Energy

Hibbeler (1989) defines mechanical efficiency as follows:

(15)

A quick look at Equation (13) of Diesel Hammers: Some Basic Thermodynamics, and the Mean Effective Pressure will show a veteran of the driven pile industry that this is not the case with diesel hammers. To understand why, let’s go back to the single-acting Warrington-Vulcan pile hammer. We saw in The Basics of Setting the Cut-Off Point for a Vulcan Single-Acting Hammer how the upward energy of the air or steam is applied to the ram so that it will reach its full stroke (energy input to the hammer.) On the downstroke the ram falls to impact (energy output from the hammer.) The impact energy of the hammer with no deduction for losses due to friction, backpressure or any other cause is given by the equation

(16)

where is the ram weight and

is the stroke of the hammer. The impact velocity resulting from such ideal conditions is

(17)

If we apply some efficiency to Equation (16), the resulting net striking energy is

(18)

and the resulting impact velocity is

(19)

This was simple enough on the face. The rated striking energy was applied directly in many dynamic formulae (especially the Engineering News formula) which was something else that compromised their accuracy. With air/steam hammers the efficiency varies considerably with the maintenance and lubrication regimen (or lack thereof) of the hammer. Additionally batter will decrease the efficiency from the plumb rated striking energy, which is discussed in The Effect of Batter on Hammer Energy.

But it’s also possible to increase the apparent efficiency of the hammer. The simplest way to do this is to apply downward assist to the ram. This is done in double- and differential-acting hammers; with these hammers, however, the effects of that downward assist are generally built into the rated energy of the hammer, as can be seen in The Differential Acting Hammer Cycle, from a Raymond Point of View. Many hydraulic hammers, however, which use downward assist to even out the oil flow (necessary with an incompressible fluid) simply use that to increase the apparent efficiency of the hammer!

And As For Diesel Hammers…

Now to the present issue: in this part we’re sticking to the single-acting tubular diesel hammers, which are by far the most common types in use. In Diesel Hammers: Some Basic Thermodynamics, and the Mean Effective Pressure it was noted that all of the diesel hammer’s energy was derived from the thermodynamic energy output of the Otto cycle (or actual approximation of same.) That energy is the expansion energy minus the compression energy, which means that, during the downstroke, the ram imparts energy for the compression of the air before combustion. While some of that pressure/force may end up moving the anvil downward, it doesn’t change the basic energy balance. The compression force reduces the acceleration of the ram during the working stroke, even though this energy is returned to the ram in the upstroke expansion phase.

This last fact has inspired some agencies to “derate” diesel hammers from what they would have in Equation (16) (20% is a common number.) Is this justified? To answer this question we need to note the following about using Equation (16) in this application:

- Diesel hammer manufacturers routinely use the maximum physically possible stroke of the ram in Equation (16) to rate the diesel hammer. It is not a good idea to run a diesel hammer with the catch ring beating the upper cylinder.

- As will be seen in subsequent posts, diesel hammers are not designed to reach the catch ring groove with the expansion energy they generate. They rely on rebound to do that (to say nothing of events such as Projectile Motion, or Why You Don’t Put Starter Fluid in a Diesel Hammer.) Rebound is basically energy the hammer puts into the pile that comes back into the hammer, and can be found with any impact pile hammer given the right resistance, pile impedance and soil conditions.

- Although beyond the scope of this series, the relationship between the ram weight and the impact velocity, along with the modulation effects of the cushion material on the force-time history at impact and the effect of combustion in diesel hammers, complicate the whole question of energy vs. hammer performance.

Given all of this, the answer to the question of derating needs to be as follows:

- Given the complicated (and frequently misleading) relationship between rated and net striking energy across the board, derating diesel hammers in an attempt to “level the playing field” will probably create as many problems as it solves.

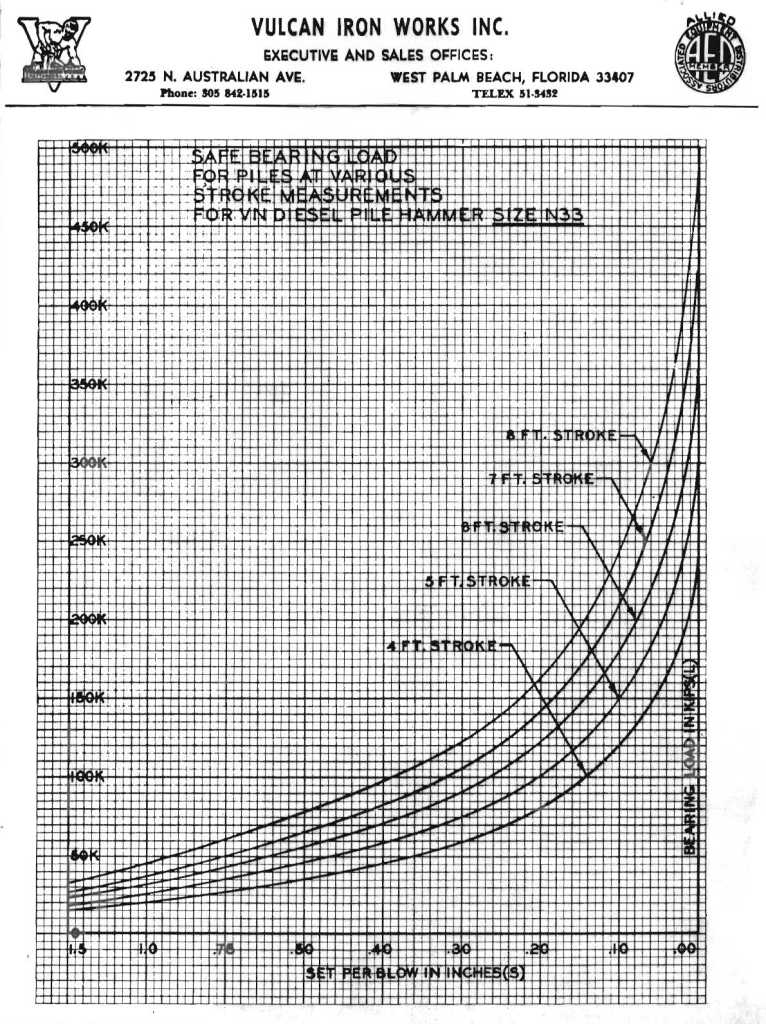

- The whole concept of “rated striking energy” should be viewed simply as a starting point in an attempt to match the right hammer with a given pile/soil combination. Experience and well performed wave equation analyses should follow this start. Different pile/soil combinations are best driven with different types of hammers; some hammers are more versatile than others.

References That Are Not Hyperlinked

Hibbeler, R.C. (1989) Engineering Mechanics: Statics and Dynamics. Fifth Edition. New York: Macmillan Publishing Company, Inc. (I taught these courses from a later edition of this book; you can see the course websites from here.)

One thought on “Diesel Hammers: Rated Striking Energy, and Should Diesel Hammers Be Derated?”