To Download This Book Click Here

About the book

A book describing various aspects of steel foundries.

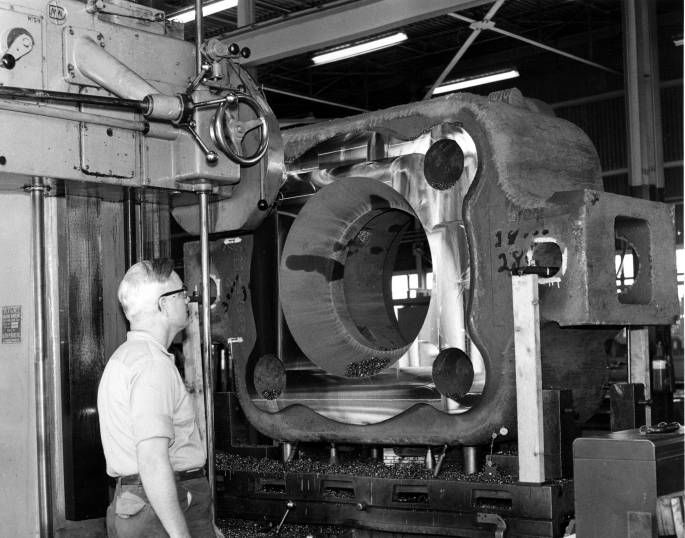

Steel castings were an important component of Vulcan hammers, especially with the bases (as you can see below) and driving accessories. The MirTitles link to the book is faulty; you can get the book by clicking here.

Table of Contents

Chapter I. Properties of Steel Castings 7

- Products of Steel Foundry 7

- Classes of Steel Castings 8

- Casting Methods 10

- Steel Casting Process 11

- Carbon Steel Castings 13

- Castings of Alloy Structural Steel 15

Chapter II. Casting and Other Engineering Properties of Steel 23

- Fluidity of Steel and Mould Filling Ability 23

- Saturation of Steel with Gases. Gas Cavities and Flakes in Castings 33

- Casting Defects Related to Moulding Sands 40

- The Effect of Nonmetallic Inclusions on Cast Steel 48

- Solidification of Steel in a Foundry Mould 56

- Shrinkage, After effects and Prevention 70

- Directional Solidification 91

- Hot Cracking, Causes and Prevention 100

- Residual Stresses, Warping and Annealing Cracks 115

Chapter III. Manufacture of Steel Castings 126

- Process Designing 128

- Moulding and Core Sands for Steel Castings 135

- Gating Systems for Steel Castings 141

- Risers. Design, Shape and Size. Calculation Methods 167

- Heating the Risers 180

- Pressure in the Risers 184

- Moulding and Mould Assembly 186

- External and Internal Chills. Application and Calculation 193

- Necked-down Risers 208

- Drying the Moulds and Cores Used for Steel Castings 210

- Steel Pouring Theory and Practice 212

- Cooling of Castings. Cooling Rates. Calculation 218

- Cleaning. Removal of Gates and Risers. 225

- Heat Treatment of Castings 226

- Finishing and Inspection 231

Chapter IV. Operating mers. of Cast Steel 233

- Carbon Steel Bae 233

- Manganese Steel 235

- Copper Steel 237

- Silico-manganese Steel 238

- Multicomponent Alloy Steels 238

- High-alloy Steels with Special Properties 245

- Austenitic Manganese Steel 246

- Stainless Steel 249

- Iron-base and Other Heat-Resistant Alloys 259

- Tools Cast from High-speed Steel 266

- The Properties of Magnetic and Nonmagnetic Alloys 267

Chapter V. Smelting Steel for Shaped Castings 269

- Side-blown Converter Process 269

- Open-hearth Process 284

- Electric Arc Process 294

- Combined Processes 308

- Vacuum Treatment of Steel 311

Index 317

First posted in Steel Foundry Practice – Bidulya — Mir Books