The length of the Nipple from the Inlet must be kept to a minimum. A long Nipple, as shown in the drawing, even though supported by chain or wire rope, will cause damaging leverage and vibration. Extensions to the side, like the arrangement in the picture, allow for good support of the Piping and Hose. … Continue reading Vulcan Onshore Tip #16: Piping Do’s and Don’ts

Vulcan Onshore Tips #15: Base Column Keys

Loose Column Keys can shorten the life of a Hammer considerably. When the Base Keys are loose the Hammer is subject to misalignment and breakage. Loose Keys will slip into the center of the Base and be struck by the Ram Point, breaking the Base. The above drawing shows a quick and easy way to … Continue reading Vulcan Onshore Tips #15: Base Column Keys

Vulcan Onshore Tip #14: Vulcan Extractors

Note: background information about Vulcan extractors can be found here.

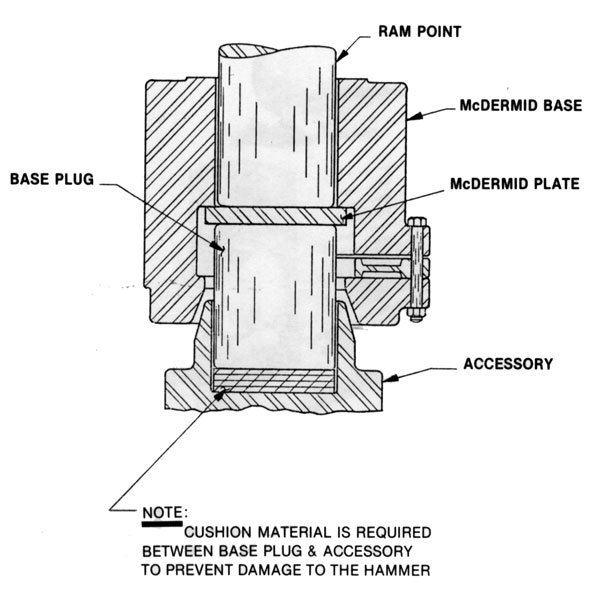

Vulcan Onshore Tip #13: Adaptation of McDermid Base

We do not recommend the use of McDermid base for any type of pile other than wood. But on occasion, contractors have found themselves in a position whom they have had to adapt a McDermid base to standard Driving Heads or Pipe Caps. The above shows the arrangement necessary to accomplish this. Note: the McDermid … Continue reading Vulcan Onshore Tip #13: Adaptation of McDermid Base

Vulcan Onshore Tip #11: Storage

Sometimes contractors forget that a Pile Driving Hammer is a machine and should be treated as such. Especially when the Hammer is to be stored for any length of time. Rust can create havoc in a Hammer. Sometimes the contractor takes a Hammer off of a job and lays it down in the yard expecting … Continue reading Vulcan Onshore Tip #11: Storage

Vulcan Onshore Tip #9: Blow Count/Energy

One of the most frequent phone calls we receive is from contractors and engineers asking "Is a Hammer delivering full energy if the blow count per minute is less than listed in the Specifications?" Blow count does not indicate full or less than full energy. A Single Acting Hammer will deliver full energy if the … Continue reading Vulcan Onshore Tip #9: Blow Count/Energy

Vulcan Onshore Tip #7: 11 Rules for Pile Driving

The Name of the Game -- Heavier Ram - Shorter Stroke Concrete piles cracking while driving in either soft silt or very hard ground? The solution is the same for both problems: Use a thicker cushion block and a hammer with a heavier ram and shorter stroke. The solution and others to related problems, comes … Continue reading Vulcan Onshore Tip #7: 11 Rules for Pile Driving

Vulcan Onshore Tip #6: Keeping Ram Keys Tight

When some hammers get enough mileage on them to warrant retirement and under certain driving conditions, the contractor may have trouble keeping the ram keys tight. Usually under these circumstances, the contractor will weld the keys to the ram and worry about the consequences later. The drawing above shows a better way of keeping the … Continue reading Vulcan Onshore Tip #6: Keeping Ram Keys Tight

Vulcan Onshore Tip #3: Valve Flutter

Under certain atmospheric conditions, a film of ice will form on the inside wall of the steam chest. This film prevents the valve from seating properly and also reduces friction between the valve and steam chest wall. In some driving conditions, this lack of friction will allow the valve to "bounce" or "flutter," needless to … Continue reading Vulcan Onshore Tip #3: Valve Flutter

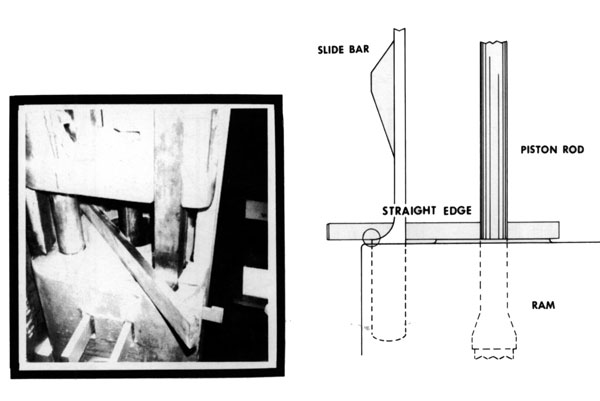

Vulcan Onshore Tip #2: Checking Slide Bar

A quick way to check the correct position of the slide bar is shown in the drawing and picture above. Place a straightedge across the machined boss area of the Ram as shown in the picture. The lower edge of the straightedge should be even with the "break" of the round stock of the slide … Continue reading Vulcan Onshore Tip #2: Checking Slide Bar