In construction practice, it is sometimes necessary to immerse thin steel pipes into the ground, used as electrodes, piezometers, injectors for cementation or chemical consolidation of soils, etc. With a short pipe length of up to 5-8 m, this operation does not present any great difficulties and is performed manually by driving. As the length increases, the work becomes more complicated and is performed with the help of special equipment and devices.

Experience has shown that the greatest effect can be achieved by immersing thin pipes with vibratory hammers. In particular, small vibratory hammers VPM-1, VPM-2 or vibratory hammers can be used for this purpose.

Based on the technology developed by the authors with the participation of M. G. Tseitlin and S. V. Plekhanova, pipes are immersed in separate links 3-4 m long, connected using couplings and locknuts.

To carry out the work you must have the following equipment and devices:

- vibratory driver (with the necessary electrical equipment);

- lifting mechanism (truck crane, inventory tripod or pile driver mounted in the back of a truck);

- guide devices, which include a stand, a roller carriage for the vibratory driver, and a centering ring for the pipe.

The general diagram of the installation for immersing pipes using a truck crane as a lifting mechanism is shown in Fig. 127.

The purpose of the guide post is to ensure the usually specified vertical direction of movement of the vibrator and pipe. At the bottom of the rack there is a support plate that distributes pressure when installing it on the ground. Two roller carriages are connected to the vibratory driver, each of which consists of a frame connected to the vibration driver and two rollers moving between the shelves of the guide post. The clamp to the piezometric pipe serves to center the pipe and reduce its transverse vibrations. The cage consists of a flange with racks installed on it, inside of which radial single-row ball bearings are reinforced.

The centering ring is located at the lower end of the guide post. Before diving, electric current is supplied, equipment and accessories are delivered, the installation is installed, i.e., the guide post is set, the cable is supplied and connected. Further operations are performed in this order:

- the vibratory driver rises along the guide post to its highest position;

- the centering clip is attached to the stand at a height of 0.3 m from the ground level;

- the first link of a pipe 4 m long is inserted into the holder, and then, using a coupling and a lock nut, previously attached to the pipe, it is screwed into the head of the vibratory driver;

- a tip is screwed onto the pipe from below and the electric motor of the vibratory driver is turned on. After the first section of the pipe is immersed, the lock nut and coupling are unscrewed from the head, the vibratory driver is released and raised to its highest position. The coupling and locknut are then unscrewed from the pipe.

The centering collar rises along the stand above the free end of the pipe. The locknut and coupling are screwed onto this end. Then a second link is inserted into the holder, which is screwed onto the head of the vibratory driver and connected to the previously immersed one. The second and subsequent links are immersed in the same order as the first.

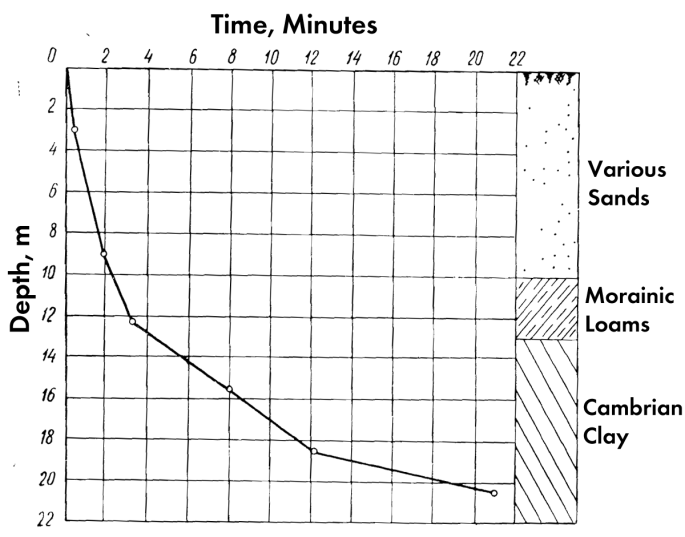

In Leningrad, an experimental immersion of steel pipes with an outer diameter of 33 mm was carried out at two sites. The soils of the first site consisted of the following strata, counting from the day surface: 0-10 m – various sands (fine-grained in the upper part of the strata, turning at the base into medium and coarse-grained with an admixture of pebbles); 10-13 m – moraine loams, dense, with a high content of pebbles, gravel and cobblestones; below 13 m – dense and heavy Cambrian clay.

The groundwater level during testing was at a depth of 1.5-2 m from the ground surface.

At the second site, immersion was carried out in a layer of sand to a depth of 7 m and an underlying thick layer of ribbon clay.

The groundwater level was at a depth of 2.4 m from the ground surface.

In both cases, pipes had to be immersed in both sandy and clayey soils. The work was carried out using the technology discussed above.

A guide post 5.5 m long was attached at its upper end to a wooden tripod equipped with a 1.5-ton hand winch. The VPM-1 vibratory driver had a head with an adapter for connecting to the submersible pipe; in order to avoid deviation of the latter from the vertical and reduce transverse vibrations, first two and then one centering cage were used.

The vibrator was connected to the guide post via a roller carriage. The immersion was carried out at an eccentric moment of 30 kg-cm.

One of the graphs of pipe immersion to a depth of 20.5 m is shown in Fig. 128. As can be seen from the graph, the total duration of operation of the vibrator was about 20 minutes; the full cycle of work, including auxiliary operations, took 1 hour 15 minutes. – 1 hour. 30 min. In all cases when centering clips were used, no significant deviations of the pipe from the vertical and strong transverse vibrations were observed.

Thus, the method described above for immersing thin steel pipes turned out to be quite reliable, quite convenient and cheap, and therefore it can be recommended for use in construction practice.

One thought on “Immersion of Thin Steel Pipes into the Ground”