For the entire book, click here. This is an interesting section for many reasons, but we can mention two: it’s the first reference in the book to diesel hammers (up to now the vibratory drivers have been competing with air/steam hammers) and it’s the first reference for letting the vibratory driver bounce on the pile head, making it an impact-vibration hammer. It’s also interesting to see the Soviets use these machines for driving concrete piles; that has been a slow adopt in American practice.

For vibration immersion into the ground of light (up to 2 tons in weight) wooden and small reinforced concrete piles, wooden sheet piles and metal pipes, vibratory drivers VPP-1, VPP-2, VPP-4, VPP-4A, V-104, V-108 and VP-2 are used.

Approximate data on the maximum dimensions of wooden piles for driving the most commonly used vibratory pile drivers VPP-4 and VPP-4A are given in Table. 36.

| Type, dimensions of piles and maximum immersion depth | Soil Characteristics | ||

| Weak soils, water-saturated loose fine-grained sands and sandy loams, silty soils | Medium dense soils, water saturated, medium and coarse-grained sands, weak clay soils | Dense soils, dry sands and natural moisture, plastic play soils | |

| Largest diameter in cm | 30 | 25 | 20 |

| Maximum immersion depth in m | 8-10 | 6-7 | 4-5 |

Wooden sheet piles of the usual sizes of length 5-6 m, thickness 12-18 cm and width 16-20 cm can be immersed to the full depth, depending on the density of the soil, in sets of two or three beams or individual piles. The same vibratory hammers can also be used to drive reinforced concrete piles with a cross-section of no higher than 25 x 25 cm and a weight of no more than 0.8 tons.

When immersing in dense, low-moisture sandy soils, an effective method is vibration immersion in combination with preliminary jetting.

Taking into account average soil conditions, the data for determining the eccentric moment of vibratory pile drivers VPP-4 and VPP-4A, depending on the weight of the driven piles, are given in Table 37.

| Weight Of The Driven Pile in t | Eccentric Moments in kg-cm |

| 0.2 | 220 |

| 0.4 | 330 |

| 0.6 | 440 |

| 0.8 | 550 |

The immersion of light piles, the cross-sectional area of which does not exceed 400 cm2, into weak and medium-density soils can be carried out without installing additional loading plates on vibratory drivers. In other cases, additional driving is required.

Vibratory pile drivers VPP-1 and VPP-2 can be used to drive piles weighing up to 1.5-2 tons and a cross-sectional area of up to 1000 cm2 into water-saturated sandy and weak clay soils. The eccentric moments and the weight of the load in each individual case are determined according to the instructions in § 4 of the first chapter.

Wooden piles and sheet piles can be driven with vibratory drivers VPP-4 and VPP-4A, as when working with metal sheet piles, using jib cranes or pile drivers.

The lifting capacity of the crane or pile driver must correspond to the total weight of the pile, the vibratory driver and the load if it is attached, and the lifting height of the hook must correspond to the length of the piles being driven. Preference should be given to jib cranes, since their productivity in this case is significantly higher than that of pile drivers.

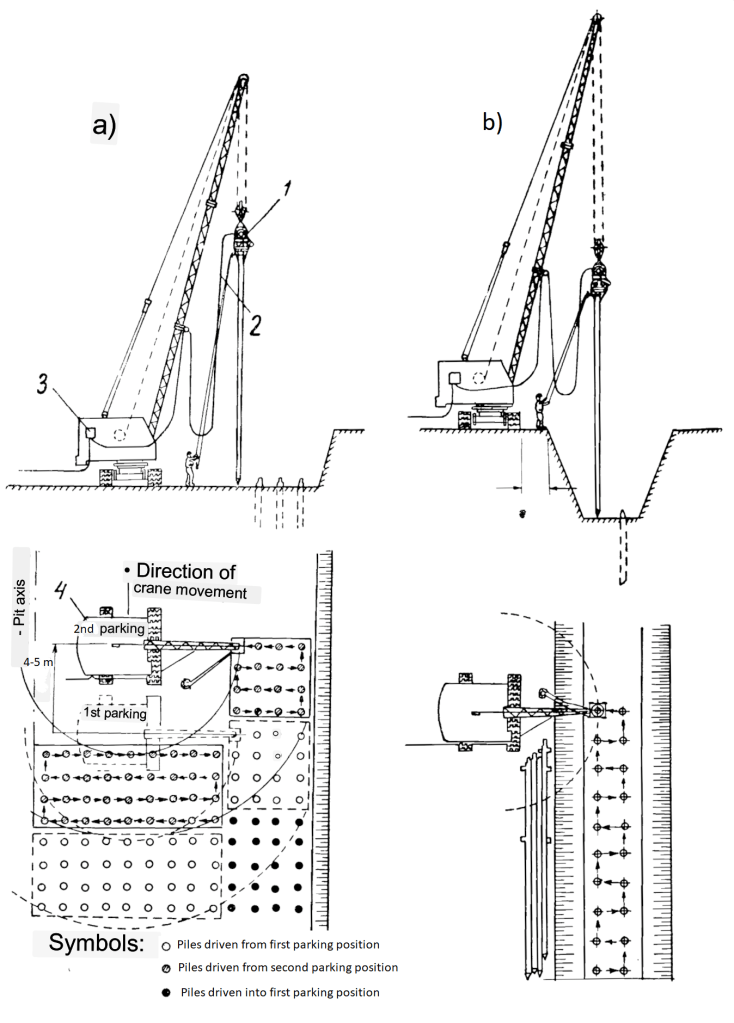

Schemes for organizing work on driving wooden piles using vibratory drivers VPP-4 and VPP-4A using jib cranes are shown in Figure 88.

a – immersing piles from the bottom of the pit;

b – when driving piles from the surface of the site,

1 – vibrating driver;

2 – current supply cable;

3 – magnetic starter:

4 – crane-excavator E-505

Artificial foundations for hydraulic engineering and industrial structures are arranged in the form of pile fields, rows or bushes. In the first case, the piles are driven from the bottom of a previously opened pit, and in the second and third cases – from the surface of the construction site.

Organization of work on driving piles includes laying out the axes of pile rows, preparing equipment and piles. Breakout work is significantly no different from that performed using hammers.

When preparing the equipment, it is necessary to:

- adjust the brakes of the crane winches,

- set the eccentric moment and load according to the above approximate data corresponding to the size of the piles, the depth of their immersion and soil conditions, and

- hang the vibratory driver on the crane hook using a sling and supply electricity to the vibratory driver.

As when immersing a metal sheet pile, the crane hook is equipped with a reliable locking device that prevents spontaneous removal of the sling.

A push-button control of the magnetic starter is installed in the crane cabin so that the vibratory driver can be turned on and off by the crane operator. On pile drivers, the push-button control is located near the winch.

Preparation of piles consists of sharpening the tip, processing the heads to secure them in the head of the vibratory driver, and applying paint to mark them in meters.

The lower end of the pile is sharpened symmetrically relative to its axis in the form of a three- or tetrahedral pyramid with a height equal to 1.5-2 times the diameter of the pile, and the point is somewhat blunted.

When designing vibratory hammers, it was assumed that they would be used only in pure vibration mode with rigid attachment to the pile. Subsequently, it turned out that in many cases, driving can also be carried out in impact-vibration mode without attaching the pile to a vibratory driver.

At present, data have not yet been compiled that would allow us to accurately establish which mode and under what conditions is the most effective.

In production conditions, both modes are used.

When a pile is rigidly fastened to a vibratory driver, its head is set up as follows (Figure 89.) The upper end is sawed off perpendicular to the axis of the pile and trimmed into two edges over a length of about 0.5 m. The planes of the trim should be parallel to the geometric axis of the pile. A hole with a diameter of 51 mm is drilled in the hewn plane at a distance of 350 mm from the end of the pile. Piles made of dry wood, if there are a significant number of cracks in the head, are additionally strengthened with a bolt (Figure 89b.)

When working without rigid fastening, the vibratory driver is equipped with a head, consisting of a piece of pipe, the internal diameter of which is 5-10 mm greater than the diameter of the pile, and a steel plate, attached to the vibrator. Preparation of the pile head in this case comes down to trimming it to the required size.

The procedure and rules for performing all operations are basically the same when using jib cranes and pile drivers.

When using a pile driver in the process of preparing equipment, it is recommended to connect the vibratory driver to the guide booms of the pile driver using pads attached to the main loading plate of the vibration driver (Figure 90.)

The full cycle of work on driving piles using vibratory hammers includes the following main operations:

a) installing a crane or pile driver with a vibratory driver in the lower position at the place where the pile is being driven; .

b) dragging the pile and connecting it to the head of the vibratory driver using a pin; c) lifting the vibratory driver together with the pile;

d) securing the pile in the cap with a ratchet wrench;

e) immersion of the pile to the design depth;

f) releasing the headrest from the vibrating hammer;

g) moving the crane or pile driver to the place where the next pile is immersed.

With rigid fastening, the connection of the pile to the head of the vibratory driver is carried out as follows. The vibratory driver is carried by a crane to the place where the prepared piles are laid (when using a pile driver, the pile is dragged to the vibratory driver using a pile cable,) then the vibratory driver is lowered onto the head of the pile so that it fits into the head with its combed edges. The vibrator is lowered until the holes in the cheeks of the head coincide with the hole in the head of the pile. After this, the head pin is inserted into the hole of the pile and secured with a retaining pin.

Before lifting the vibrator, the movable plate of the head clamping device is moved to the uppermost position by swinging the ratchet wrench, and the wrench pawl moves to the position corresponding to the lowering of the movable plate. After this operation, they begin to lift the vibratory driver from the pile. Rotating around the axis of the head pin, the pile, rising upward, will move from a horizontal to a vertical position. In this case, measures should be taken to prevent damage to the tip.

When the pile reaches a vertical position, the lifting stops. Before installing it on the ground, by swinging the ratchet wrench using rope rods, the movable plate of the head is pressed against the end of the pile, ensuring their rigid connection. After securing, the pile is installed above the immersion site and, after checking the correctness of its position, the immersion begins.

The lowering speed of the crane hook in the initial stage of immersion should be such that the pile appears partially suspended. This ensures its strictly vertical, stable position during immersion.

When connecting the vibratory driver to the guide arms of the pile driver, the immersion speed should not be limited; The hook of the lifting rope in this case lowers with some advance.

During immersion, due to crushing of the wood, some weakening of the pile head in the cap may occur.

In this case, rope rods attached to a ratchet wrench, selected as the pile is immersed, additionally secure the pile in the cap without stopping its movement.

When the design depth is reached, the electric motor of the vibratory driver is turned off and the cap is released from the pile.

Observation data on the speed and depth of immersion of each pile are recorded in a special journal.

The work technology discussed above was first applied at one of the facilities of the Leningrad administration of the Sevaapmorgidrostroy trust. At this site, initially it took up to 25 minutes to drive one pile, which was explained by insufficient training of technical personnel and lack of work experience. When the process of vibration immersion of wooden piles was mastered, this time was reduced to 12-15 minutes.

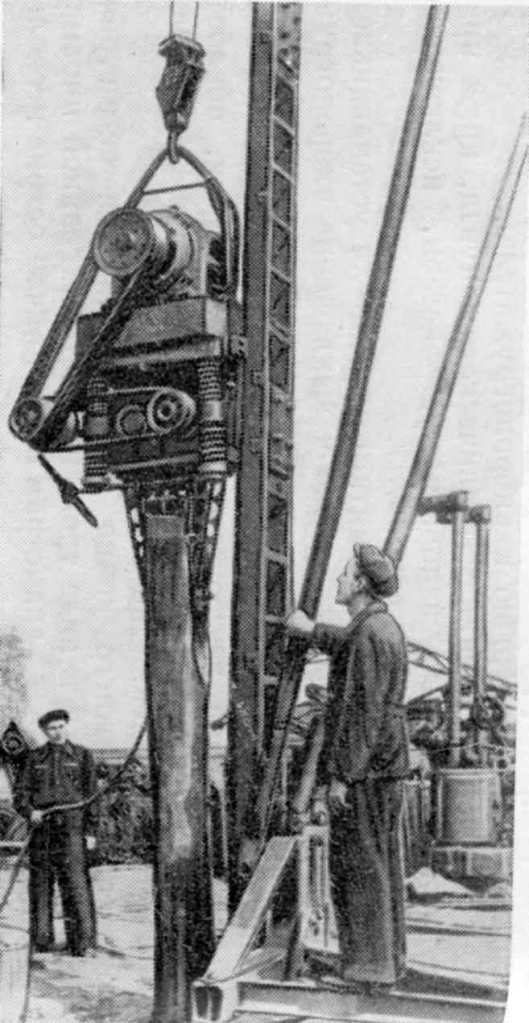

The experience of using the VPP-4 vibratory driver for driving wooden piles, accumulated by the Leningrad department of the Gidrospetsfundamentstroy trust, is indicative. A team of pitman L.T. Danilin, consisting of five people, was working on the construction of a bank reinforcement, consisting of a continuous row of wooden piles 6.5 m long, driven from a pile driver installed on a pontoon, driving up to 50 piles per shift. The team was the first to use the driving of wooden piles without rigidly fastening them. For this purpose, the clamping device and pin were removed from the conventional headrest. Instead, two strips were welded to the cheeks of the head plate, which formed a box into which the head of the pile fit, hewn to the size of this box.

The pile was lifted using a pile cable with the vibratory driver raised. After its installation, the vibratory driver was lowered onto the head of the pile and immediately started working. Driving a pile to a depth of 5-5.5 m lasted about 1-1.5 minutes, with some piles jammed in the head box and vibrating along with the vibrator body, while others sank into the ground under the influence of head impacts, following each other at a frequency , equal to the number of revolutions of the eccentrics.

Subsequently, using a new cap from a piece of pipe with a diameter of 277 mm welded to the slab, I. T. Danilin’s team drove 64 piles per shift, exceeding the norm by eight times.

In the operating workshop of the Russian Diesel plant in Leningrad, it was necessary to drive 95 wooden piles with an average diameter of 24 cm and a length of 7 m under the foundation of the test stand. This work was assigned to the Leningrad department of the Gidrospetsfundamentstroy trust. The placement of equipment near the pit of the stand under construction did not allow the use of jib cranes or conventional type pile drivers. It was decided to carry out the driving with a vibrating hammer using an overhead crane. The base soils up to 5 m are represented by ribbon clays and below – water-saturated sandy loams.

A pad eye was welded to the side of the tubular headplate, to which a piece of cable with a diameter of 12 mm was attached. The vibratory driver, suspended on the hook of the overhead crane, was brought to the pile prepared for loading. The cable hanging from the head was attached in a loop to the pile at a distance of about 1 m from the top end. At approximately the same place on the pile, three braces made of hemp rope with a diameter of 14 mm were fixed.

To prevent the lifting cable and braces from sliding down the pile, they can be secured with a construction bracket driven into the body of the pile.

The crane lifted the pile secured in this way simultaneously with the lifting of the vibratory driver and transported it to the driving site. A worker located at the bottom of the pit installed the tip of the pile in the right place, and three workers located outside the pit used braces to hold the pile in an upright position. Then, at the signal from the foreman, the crane operator lowered the vibratory driver onto the head of the pile, turned on the motor and, as the pile immersed, smoothly lowered the vibratory driver. The pile was held in a vertical position by braces only for the first 2-3 m. Further immersion proceeded without tension on the braces. When the pile reached a driving depth of 5.5-6.5 m, the vibratory driver was turned off, the lifting cable and braces were removed from the pile, after which further driving was carried out. All 95 piles were driven into the foundation in 12 hours.

At some sites, VPP-2 vibratory pile drivers were used to drive long wooden piles. They were equipped with a special cap, with the help of which the pile was rigidly fastened to the vibrating clamp. Thus, at Stalingradgidrostroy, for the VPP-2 vibratory hammers, caps with ratcheting wrenches were made, the same as for the VPP-4 vibratory hammers. The Sevzapmorgidrostroy trust designed a head for the VPP-2 vibratory driver, in which the head of a wooden pile was clamped as if in a vice.

The Riga construction department of the Baltspetsgidrostroy trust needed to drive several hundred wooden piles 12 m long into the base of the supports of the bridge, the soil of which is water-saturated sand. The supports were erected in pits 7-8 m deep, the walls of which were fenced with metal sheet piles of the Larssen IV type, immersed into the ground with the vibratory driver VPP-2.

To drive the wooden piles, the same vibratory driver was used, but with a different head, as well as a crawler crane, which was used to load the sheet piles.

The piles were prepared for driving as usual, with the difference that the side chamfers at the end were not removed.

The sequence of individual operations in the pile driving cycle was similar to that used for metal sheet piles.

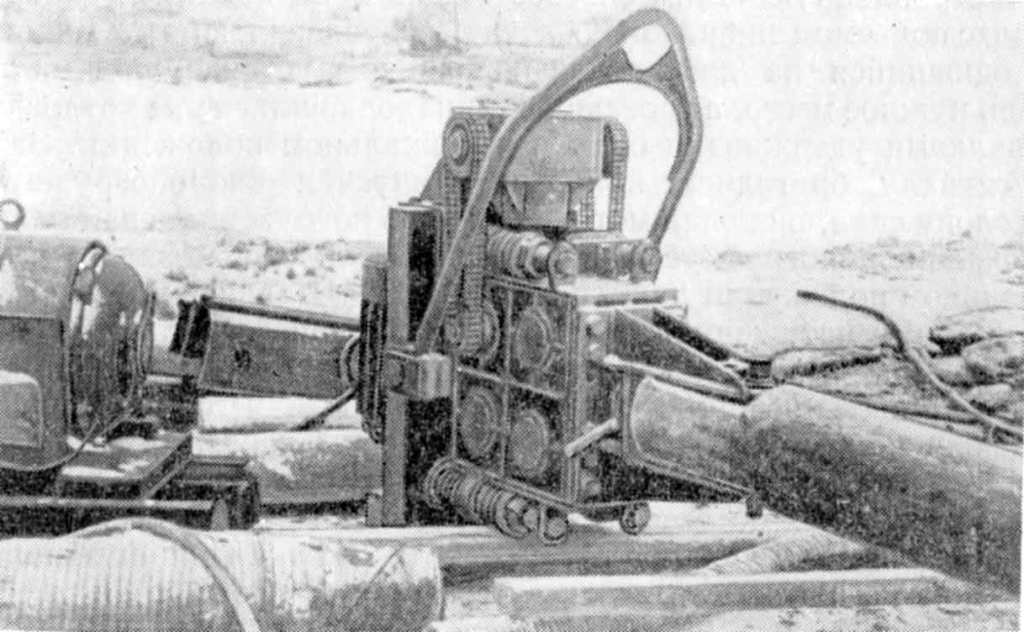

To fasten it to the pile, the vibratory driver was rotated to a horizontal position and moved onto the head of the pile. Then the pin was inserted, as well as the retaining pin, and by rotating the handwheel, the movable plate strongly pressed the pile against the pin. In some cases, it turned out to be more convenient to drive the pile into the head of a vibratory driver laid on pads (Figure 91.)

After fastening, the pile and vibratory driver were lifted by crane and transferred to the pit for installation in the desired location.

The pile was immersed with mandatory braking, which ensured its vertical position (Figure 92.) When the head reached the level of the top of the pit, the vibratory driver stopped and the head screw was tightened, since due to the crushing of the wood, the pile and the head were partially weakened. Then the pile was immersed to its full depth without stopping.

The immersion of wooden sheet piles is carried out using basically the same techniques and in the same sequence as for wooden piles with a slight difference when immersing the sheet piles in packages. For such work, vibratory hammers must be equipped with special caps corresponding to the thickness of the sheet pile.

To immerse wooden sheet piles in batches, vibratory drivers that can be easily moved to a horizontal position can be successfully used: VPP-4A, VPP-2, V-108, VPP-5, VPP-6 and others. The technology of work in this case basically coincides with the technology of immersing metal sheet piles. There are significant differences only in the methods of attaching the package with the vibrating hammer.

During the laying of heating pipelines by the Sevenergostroy trust in the city of Kirovsk, a sheet pile 12 cm thick and 16-20 cm wide was immersed in water-saturated fine-grained sandy soils to a depth of 6.5 m. The work was carried out with a metal pile driver. The sheet piles were not driven in batches, but in separate piles. The vibrator was set to a minimum eccentric torque of 220 kg-cm. The immersion was successful without an additional loading plate. To connect the sheet pile to the vibratory driver, a pile cap was used, but since the width between its cheeks, equal to 22 cm, significantly exceeded the thickness of the sheet pile (12 cm,) then on each pile in the upper part, overlays from scraps of boards of such thickness were affixed onto each pile with nails so that the pile the pads fit into the headrest. Otherwise, the work was carried out as if driving piles.

During the construction of a residential building, sheet piling work was entrusted to the Leningrad department of the Gidrospetsfundamentstroy trust. it was necessary to immerse sheet piles of the same dimensions into soils that turned out to be much more dense. The degree of density is indicated by the following: attempts to load the sheet pile with hanging heads weighing 600 kg, then 1200 kg and, finally, a single-action hammer weighing 1800 kg were unsuccessful. Then it was decided to check the possibility of using the VPP-4 vibratory driver.

To immerse the sheet piles in packages of three piles, the soil structure was somewhat destroyed by preliminary undermining using a 1.5-inch pipe about 6 m long, equipped with a nozzle at the end. Water from a small centrifugal pump was supplied to the pipe through a rubber hose. The pipe sank into the ground under the pressure of water and was immediately removed. A package of sheet piles was placed in the same place, connected to a vibrating hammer suspended from a wooden pile driver. As in the first case, the work was carried out without additional loading with a minimum eccentric moment of the vibratory driver.

The connection of the sheet piling package with the vibratory driver was made as usual, with the same head, using a pin; Inside the headband, channel cuttings were welded to the cheeks, which eliminated the need to stuff pads on each package.

The work of immersing the sheet pile in batches with preliminary partial washing was carried out by a team of three people. Despite the fact that moving the wooden pile driver and cleaning work took a relatively long time, the team drove 12-14 packages per shift.

A large amount of work on driving wooden sheet piles 16 cm thick and 6.5 m long was carried out by the Riga Construction Department of the Baltspeshgidrostroy trust during the construction of the water supply and discharge channels of the thermal power plant. In the initial period, the sheet pile was driven from RMK-5 pile drivers using diesel hammer packages with a hammer weight of 1200 kg. Then, in combination with the same pile driver, the VPP-4 vibratory driver was used. With the same number of personnel, the team drove 2-2.5 times more sheet pile than diesel hammers, and with significantly better quality of work.

At the same sites, VPP-2 vibratory pile drivers were used to load wooden sheet piles in packages of three beams.

It is interesting to note that at some sites, wooden sheet piles were sunk into the ground without being rigidly fastened to the vibrating hammer. For example, the Sevenergostroy trust used VPP-4 vibratory pile drivers to drive 5-8 cm thick wooden sheet piles during trench work. After excavating the trench to a depth of 0.8-1 m, a wooden sheet piling, with the help of guide bars, was preliminarily driven into the wall, which, as the trench deepened, settled into the ground in steps of 0.5-0.8 m. To perform this work, the vibratory driver was equipped with a head, consisting of two jaws 1 m wide, welded to a plate, with the help of which it was attached to the bottom of the Vibrator. For greater rigidity, two gussets were welded to each of the cheeks and the plate.

To lift the vibratory loader, a truck crane with a lifting capacity of 3 tons was used. With the help of the crane, the vibratory loader was installed on the sheet pile wall and held there during the entire period of work. When the electric motor was turned on, the vibrator mechanism, together with the headplate, performed the functions of a high-frequency hammer, the operation of which ensured the immersion of the sheet pile into the ground at a speed of 0.3-0.5 m/min. Having settled a part of the wall 1 m long to a certain depth, the vibratory driver was turned off and moved to the next section. By successive rearrangements, the sheet piling walls were driven to their full depth as the trench deepened. This method of work turned out to be effective only for driving sheet piles. To remove the tongue, a clamping type head is required, which provides rigid fastening of the sheet pile package with the vibrating driver.

In construction practice, there are many examples of successful use of vibratory drivers of the VPP type for driving small reinforced concrete piles.

In recent years, in the construction of power transmission lines, pile foundations for supports have begun to be widely used instead of conventional concrete ones, installed in a pit with the installation of formwork and concreting on site. Under each support it is necessary to drive four reinforced concrete piles, the dimensions of which can vary within the following limits: the cross-section, from 22 x 22 cm to 40 x 40 cm, and the length from 4.5 m to 7 m.

In the first period, to construct the foundations of power transmission line supports, piles were driven with a mechanical hammer from a self-propelled pile driver mounted on the basis of a Type DT-54 crawler tractor. Later other methods began to be used.

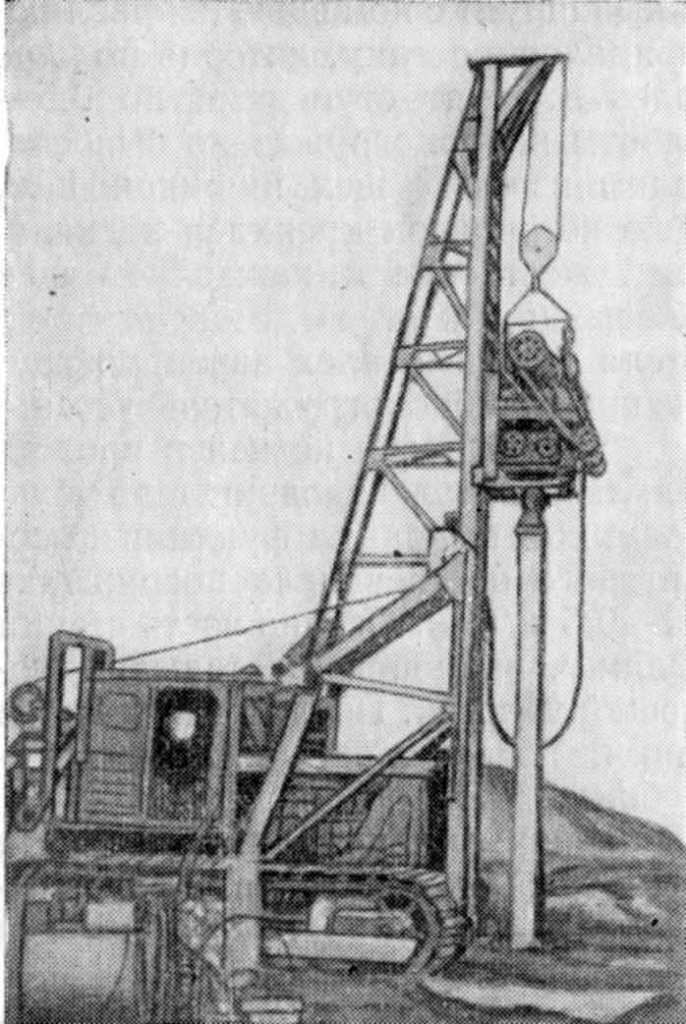

In the Denelektrosetstroy trust [9], a self-propelled unit was designed for driving reinforced concrete piles with a cross-section of 22 x 22 cm and a length of 4.5 m (Figure 93.) This unit consists of a tractor S-80 with a chassis extended by 900 mm and a reconstructed cabin, a vibratory driver VPP-4B connected to the guides of a metal boom and equipped with a special head for fastening to a pile, an electric generator SG-60/6 with a power of 57 kVA, voltage 400 V and a single-drum friction winch type T-109 with a lifting capacity of 1 ton. The generator and winch are driven by the tractor engine from the power take-off roller.

The pile is fastened to the vibratory driver using a steel cap with a 52 mm diameter hole for the connecting pin.

The technology for driving piles using this unit is somewhat different from the usual one. The pile lying on the ground is raised to insert the cap into the cap using a removable lanyard: after inserting the pin and lifting the vibratory driver by rotating the pile (with a special key,) its cap is pressed tightly against the jacking screw of the cap. After the pile is immersed, the cap is released by rotating the screw itself.

As practice has shown, in some cases it is advisable to use a special metal pile of a smaller cross-section for preliminary piercing of the soil, into which the reinforced concrete pile is then immersed. The use of a leader pile extends the period of work, but also provides advantages:

- increasing the accuracy of driving piles under supports;

- probing the soil to determine the presence of rocks, boulders and other obstacles;

- a significant reduction in the time of driving a pile into relatively dense soils.

It should be noted that the vibrational immersion of reinforced concrete piles into a leader hole of a smaller cross-section does not significantly reduce the resistance of the piles to extraction, which is very important in the operation of the support foundation. Thus, according to the Lenelektrosststroy trust, a pile with a cross-section of 22 x 22 cm, buried in the ground in the specified manner to a depth of 3.2 m, can withstand an extractive force equal to 10-12 tons, and a pile with a cross-section of 20 x 20 cm, buried to a depth of 5.3 m, can withstand 17.5-22.5 tons.

Experience has shown that the units can be successfully used for immersion in sandy and weak clay soils both in summer and winter. Immersion of a pile with a cross section of 22 x 22 cm, up to 5 m long, into weak clay soils lasts on average 6-10 minutes, and in sandy soils – 2-2.5 times less. Immersion in dense clay soils, even with the installation of a leader hole, sometimes takes up to 60 minutes.

It is necessary to point out that the parameters of the VPP-4 vibratory driver, mainly its weight, are insufficient for dense soils. Therefore, a winch was installed on one unit, which, if necessary, creates an additional load on the pile of 1-1.2 tons. Practice has confirmed the effectiveness of this device.

Trust Sevzaptransstroy used a VPP-4 vibratory driver to drive reinforced concrete piles with a cross-section of 25 x 25 cm and a length of 6 m using a railway jib crane. The work was carried out using technology similar to that used for wooden piles.

To articulate the pile with the cap at its head, at a distance of 350 mm from the end, a metal tube with an internal diameter of 52 mm and a length of 250 mm was embedded in the concrete and welded to the reinforcement. The distance between the cheeks of the head was 26 cm instead of 22 cm for wooden piles. a piece of board was attached to the pressure plate, through which the plate was pressed against the end of the pile during operation of the ratchet wrench.

Vibratory driving of reinforced concrete piles at this site resulted in savings of over half a million rubles.

The driving of metal tubular piles, closed at the bottom, is carried out using basically the same techniques as wooden and light reinforced concrete ones. Some difference is associated with the need to resolve the issue of the design of the device for rigidly connecting the immersed element to the vibratory driver and the methods for performing this operation. At present, there is not yet a universal device for this purpose, therefore, depending on local conditions and the design of the elements being immersed, in each case the issue is resolved individually. So, for example, at one of the facilities of the Leningrad administration of the Sevzapmorgidrostroy trust, when vibrating tubular steel piles closed at the bottom with a length of 20 m and a diameter of 377 mm, the connection of each pile and the vibratory driver was carried out using an adapter having two plates. The adapter was attached to the vibratory hammer with bolts passing through the top plate. There were holes in the bottom plate into which bolts were inserted, specially welded to the top of the pipe. The bolts were welded according to a pattern consistent with the holes in the bottom plate.

At another site, a cap designed for wooden piles was adapted to connect the vibratory driver to tubular steel piles. A beam was welded to the movable plate of the pressing device, the length of which was slightly greater than the width of the pile. An additional light beam of the same length, made from channels, was inserted into specially cut square holes in the upper part of the immersed element. This method of attaching the vibratory driver has fully justified itself.

When pile drivers are used to drive piles using the VPP-1 vibratory driver (Figure 94,) the work technology is similar to that used when working with hammers, with the difference that the vibratory driver is fastened to the pile in a vertical position.

One thought on “Vibratory Driving of Light Piles”