For the entire book, click here. This is something of the “Holy Grail” of the whole vibratory project: the ability to estimate the static capacity of piles driven by vibration. The Soviets took up the question early in the development of these machines and ran into the same obstacles that most everyone since then has done. As a general rule, the Soviets found that piles driven by vibration had a lower static axial capacity then those driven by impact. The Soviets found themselves doing the same thing that is current practice today: driving a pile by vibration and then finishing it off with an impact hammer. Although progress has been made, we still have a considerable way to go before we can use vibratory drivers without the assistance of impact ones when bearing piles are being driven.

The question of the load-bearing capacity of piles during piling work is of great practical importance. In the vast majority of cases, piles are immersed in the ground precisely in order to carry a structural load for a long time, and the deformations of the foundation and structure erected on a pile foundation should not exceed permissible limits.

It is also known that for piles driven into the ground by hammers, there are various methods for calculating the critical resistance and methods for determining the load-bearing capacity of piles in situ, proven by research and many years of practice.

Issues related to the operation of piles immersed in vibration have not yet been sufficiently studied. There are known studies and observations carried out in this area by A. M. Rukavtsov, E. M. Perley [44] and Yu. V. Makarov [30], as well as production vibration data accumulated by research tests of piles driven by institutes and some construction organizations.

Static tests carried out in accordance with the existing methodology have established that the critical resistance of reinforced concrete piles with a cross section of 30 x 30 cm and 35 x 35 cm, immersed with a VP-1 vibratory hammer into sandy and sandy loam soils to a depth of 4-7 m, reaches 50-70 tons, which, with a design load on such piles of 25-35 tons, ensures their reliable operation in the structure. However, as follows from published data [23], at some sites such critical loads were obtained only after the piles driven by a VP-1 vibratory driver were finished off with a diesel hammer with an impact part weighing 1200 kg. In one case, when finishing 40 of the piles, the additional immersion on average was 0.18 m and did not exceed 0.6 m. At another site, when adding 52 piles, the additional immersion ranged from 0.7-1.5 m, averaging 1.05 m.

Very indicative data were obtained by the Department of Foundations and Foundations of the Leningrad Institute of Railway Transport Engineers when, in collaboration with Lenmostostroy, experimental work was carried out on the construction of the Freedom Bridge in Leningrad.* Without touching on the entire complex of research work carried out at this facility, we will consider only part of them related to studying the bearing capacity of piles.

* P. V. Andreevsky, Abstracts of the report “Experimental work on driving reinforced concrete piles and driving reinforced concrete piles in the supports of the Freedom Bridge”, XIX Scientific and Technical Conference of LIIZhT, 1957.

At a site located in the immediate vicinity of the bridge, experimental driving of reinforced concrete and steel tubular piles was carried out using various methods, and their load-bearing capacity was determined. Of the total, two reinforced concrete tubular piles (No. 33 and No. 35) with a diameter of 500 mm were driven by a VP-3 vibratory driver to a depth of 18 m into the soil, the upper layers of which, to a depth of 6-8 m, are weak ribbon loams; further, to a depth of 16-19 m, medium-density silty loams occur (upper moraine), and below – dense loams with inclusions of gravel, pebbles and boulders (lower moraine).

The results of static tests of these two piles are given in Table. 40.

| Indicators | First Test | Second Test | Third Test | |

| Relaxation Time | One Month | 1.5-2 Months | 7.5 Months | |

| Critical Load, tons | Pile No. 33 | 140 | 160 | 210 |

| Pile No. 35 | 120 | 140 | 200 | |

Of great interest is the comparison of the data in Table 40 with the results of static tests of the same piles No. 16 and No. 31, hammered and jetted, finished with a 6-ton single-acting hammer (Table 41).

| Pile Number | Driving Method | Duration of Rest | Critical Resistance, tons |

| 16 | Driving with Pre-excavating and Subsequent Finishing | Approx. 1 Month | 200 |

| 31 | By 0.5 m with an air/steam hammer, single-acting, 6 ton ram | 3 Months | 260 |

From Tables 40 and 41 it can be seen that the critical resistance of piles driven by a VP-3 vibratory driver turned out to be approximately 30% lower than the critical resistance of piles driven with a hammer.

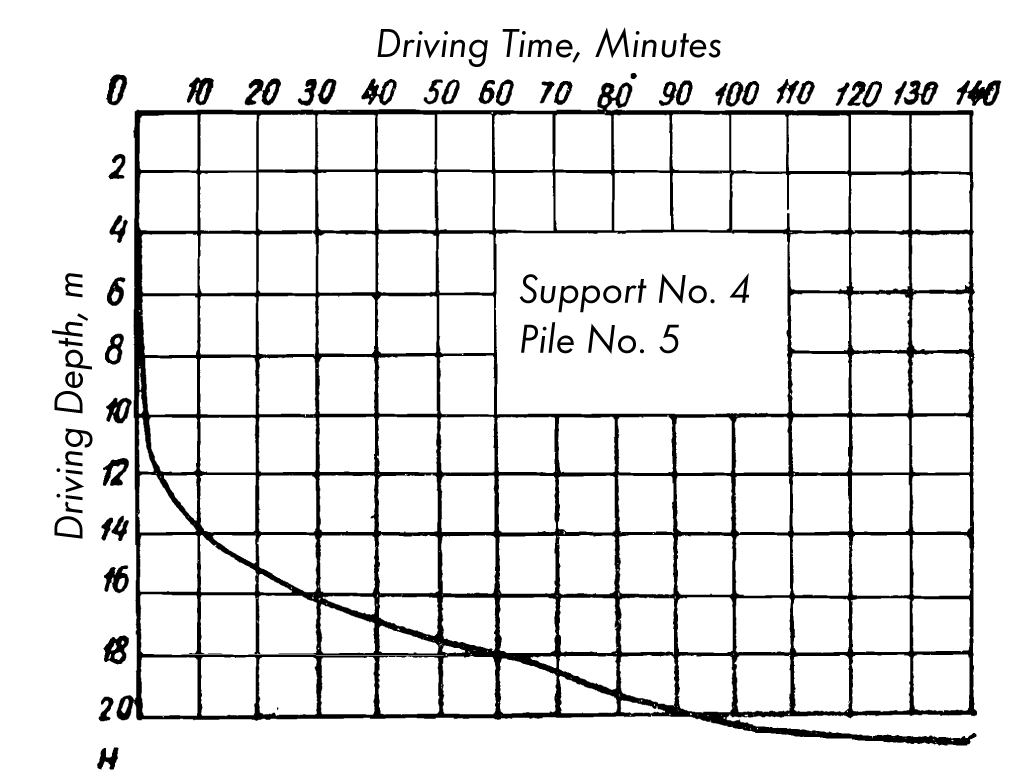

About 240 hollow piles with a diameter of 560 mm and a length of 26 m were driven under the bridge supports to a depth of 20-21 m using a VP-3 vibratory driver. From the graph (Figure 100) it is clear that in the first 10 minutes the pile was driven to a depth of 14 m. The next 6 m were driven in 80 min, and the final 1 m was driven in about 50 minutes.

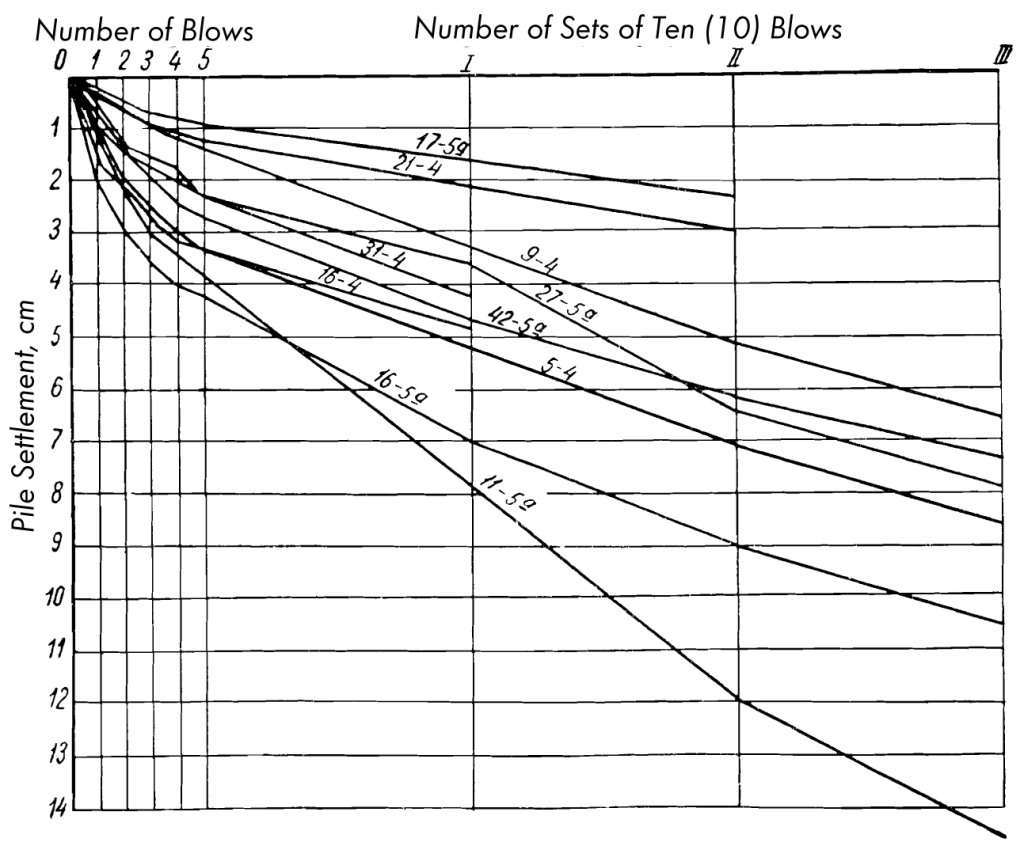

It is interesting to note that during finishing tests, the first hammer blows on the pile (Fig. 101) caused relatively large settlements. As can be seen from the graphs, the total settlement of the piles after 35 impacts fluctuated within 5-15 cm. Pile no. 5 on Support no. 4, which had a final speed of 2 cm/min (see Fig. 100,) from the first five blows of a hammer weighing 6 tons, with a drop height of 1 m, it had a failure equal to 33 mm; the total movement from 35 blows was 86 mm.

The experimental results suggest that during vibrational immersion of piles into clayey soils, a certain zone of soil with a disturbed structure is formed under their tip, and, possibly, a liquid “lubricant” appears at the side surfaces, which significantly reduces the load-bearing capacity of the piles. This phenomenon, in particular, is confirmed by static tests of experienced No. 33 and No. 35. Such a significant increase in critical resistance with each subsequent test of piles (see Table 40) is apparently explained by the fact that during the first test, the settlement of the pile passed through the zone of destroyed soil, as a result of which the critical resistance during the subsequent test increased by 1.5 times. Of course, the result of the experiment was also influenced by the restoration of structural connections in the soil during the “rest” of the pile.

Research carried out by A. M. Rukavtsov and E. M. Perley [44] generally confirmed the above data. The experiments they carried out consisted of static and dynamic comparative tests of wooden, metal pipes and reinforced concrete piles driven by a three-ton single-action hammer and vibratory hammers VP-1 and VPP-1.

To a depth of 8-9 m from the day surface of the experimental site there are soils consisting of slightly silted sands and sandy loams, refilled more than 40 years ago, at a depth of 8-9 m a layer of peat 0.5 m thick and a layer of water-saturated sand of the same thickness, and below there is a large thickness of ribbon clays.

In total, 6 wooden piles with a diameter of 320 mm and a length of 11 m were driven, the same number of metal tubular piles with a diameter of 325 mm and a length of 11 m and 9 reinforced concrete piles with a cross section of 30 x 30 cm and a length of 8.5 m. All piles were driven almost to their entire length. Thus, the points of wooden and steel tubular piles hung in a layer of strip clay, and the points of reinforced concrete – in a layer of sand.

Of the six wooden piles, two (No. 21 and No. 22) were driven with a hammer, two (No. 13 and No. 26) with a VP-1 vibratory driver, and two (No. 23 and No. 24) with a VPP-1 vibratory driver. The load-bearing capacity of some piles was tested statically, while others were tested dynamically. It should be emphasized that in all cases the results of dynamic and static tests coincided.

Both dynamic and static tests were carried out after 1-2 hours, after 15 days and after 60-200 days after immersion.

Wooden pile no. 23, driven with a vibratory driver, during static tests had a critical load of about 65 tons, and the same pile No. 22, driven with a hammer – 90 tons. Dynamic tests of other wooden piles after “rest” showed that the load-bearing capacity of piles driven with hammers is greater than those driven with vibratory hammers.

Tests on metal tubular piles yielded similar results. Static tests of pile No. 11, immersed by vibration, found its critical resistance equal to 50 tons. The same tests of pile No. 9, hammered, revealed a critical load of 70 tons.

All nine reinforced concrete piles driven by hammer and vibrator were tested only dynamically, and failures were approximately equal for all piles, regardless of the equipment used for driving them. This indicates that the load-bearing capacity of friction piles, the tip of which is in a layer of fine-grained sand, is the same for both driven and vibrating piles.

The results obtained allowed us to draw the following conclusions:

- The bearing capacity of piles driven with hammers or immersed by vibration into fine-grained sandy soils to the same depth, other things being equal, has almost the same value.

- The critical resistance of hanging piles immersed by vibration in tape clays in the early stages is approximately 30-40% less than the critical resistance of the same piles driven with a single-action hammer to the same depth.

The study that was carried out by Yu. V. Makarov [30] concerns the operation of piles driven by a VP-1 vibratory driver into sandy soils. During the research, observations were made of the immersion of reinforced concrete piles with a cross-section of 30 x 30 cm and a length of 8.4 m to a depth of 5-8 m, as well as dynamic and static tests of these piles. The soils of the site were represented by fine-grained wet sand of medium density, which lay in a layer of 8-9 m and was underlain by a layer of loam with an admixture of gravel and pebbles. As a result, it was found that when piles are driven by vibration into sandy soils, soil compaction occurs to a much greater extent than when driven with hammers, which results in a higher critical resistance of piles driven by vibration.

At present, it is premature to generalize the conclusions obtained as a result of these studies and to extend these conclusions to all types of soils encountered in practice. It is necessary to carry out a lot of experimental research and production observations in order to obtain reliable data characterizing the performance of suspended piles in various soil conditions.

The theoretical studies carried out to date in the field of vibration driving, unfortunately, do not address issues related to the operation of piles.

Therefore, there are still no reliable methods that make it possible to calculate, before or after vibrational immersion of a pile into the ground, its load-bearing capacity based on objective indications of the gels of the immersion process, in the same way as is done with the impact method of piling work.

In this regard, reliable control of the bearing capacity of piles driven by vibration can only be carried out by static or dynamic testing.

One thought on “About the Bearing Capacity of Piles Driven by Vibration”