For the rest of the book, click here.

With the right choice of equipment and organization of work, vibratory extraction of sheet piles, as well as driving, makes it possible to use stock metal sheet piles more widely than before, which contributes to a sharp increase in labor productivity and a reduction in the cost of work.

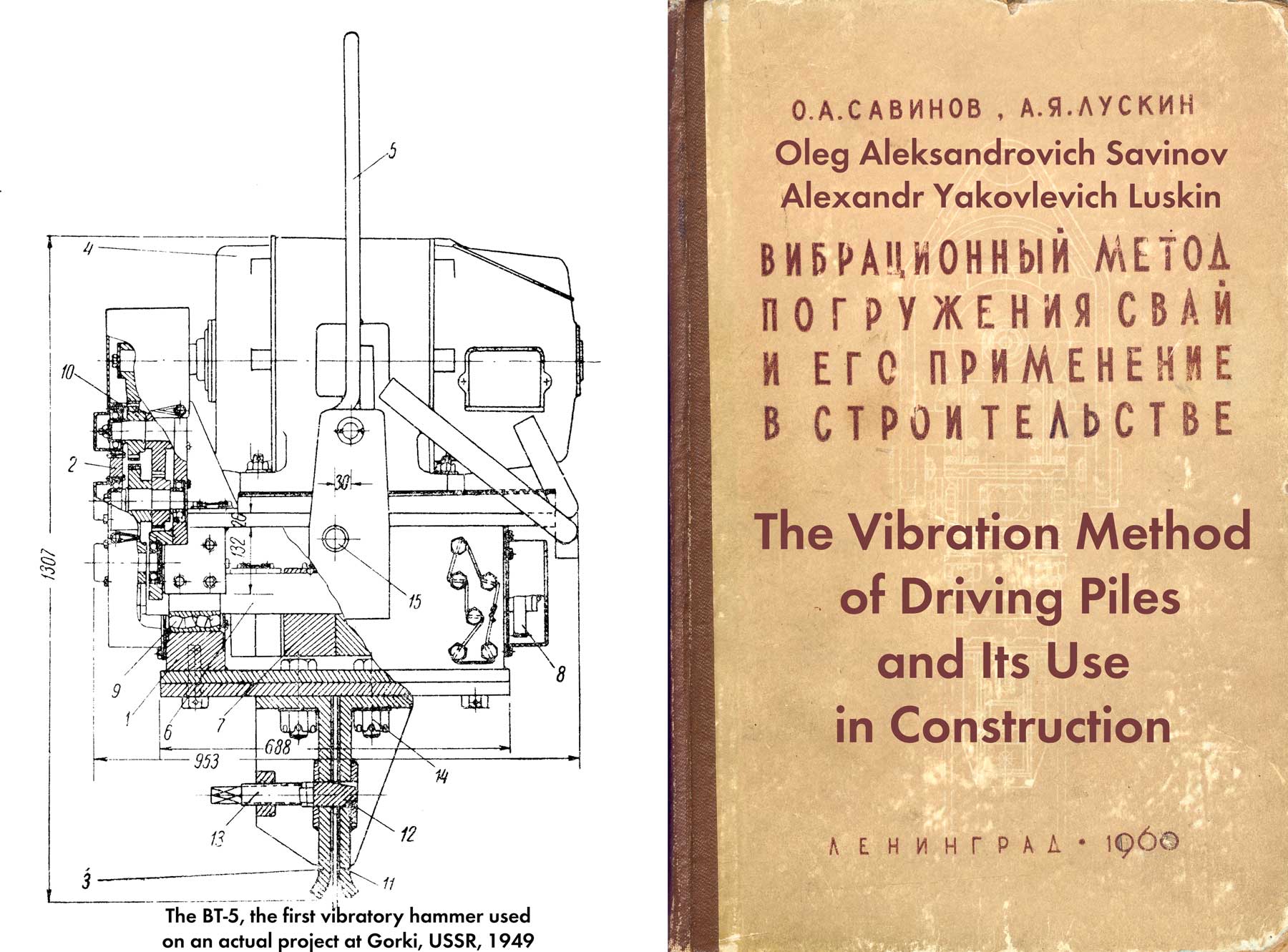

To extract metal piles when dismantling sheet piling rows, a BT-5 vibratory driver was used for the first time in production conditions. In practice, one day it was necessary to dismantle walls made of ShK type sheet piles 9.5 m long, driven into sandy soil to a depth of about 6.5 m. The total length of the walls was about 120 m. A pile driver equipped with a manual one and a half ton winch was used as a lifting mechanism .

Despite the imperfect equipment, the sheet pile row was dismantled in a relatively short time. The time to remove one pile was 41 minutes. instead of 2 hours spent pulling with a static load, without vibration.

The holes in the sheet piles for fastening to the head of the vibratory hammer were cut by a gas cutter. This was included in the brigade only for the duration of the work. The sheet pile was removed using a hand winch. The winch cable, passed through the top block of the pile driver, had a hook at the end that was connected to the suspension of the vibratory driver. This operation was carried out by four workers.

The average time spent on performing individual operations of the entire cycle of work to extract one pile is given in the table. 31.

| Name of operations | Time in minutes |

| Cutting a hole in the sheet pile and other preparatory work | 7.5 |

| Attaching the vibratory driver to the sheet pile | 6.1 |

| Removing the pile | 8.0 |

| Lowering the vibrator with the pile and releasing it by the head cap | 8.2 |

| Moving the pile driver without turning at corners | 11.2 |

Noteworthy is the fact that before removal, each pile was vibrated for 1-2 minutes. Consequently, extraction was carried out at an average speed of approximately 1 m/min, and a force of 1.5-2 tons was sufficient to overcome the resistance. Direct connection of the winch cable to a vibratory driver without a shock absorber partially reduced the vibration amplitudes of the extracted pile due to the transmission of vibrations to the entire pile driver.

Since 1952 VPP-2 vibratory drivers began to be used for vibration extraction of metal sheet piles. At the facilities of the Leningrad administration of the Sevzapmorgidrostroy trust [45], they almost completely replaced low-productivity air-steam pile pullers. In recent years, extensive work has been carried out to extract Larsen III and IV type sheet piles up to 18 m long, buried 8-15 m into the ground.

The removal of sheet piles was carried out mainly using lifting jib cranes. Only at certain sites were pile drivers used as lifting equipment. Of course, when extracting sheet piles, labor productivity when working with pile drivers was significantly lower than when working with cranes.

It took an average of 12 to 22 minutes to remove one pile when using cranes. When using pile drivers, the time required increased to 30-35 minutes. At the same time, the crew’s productivity per shift on the work performed using a crane should have been 30-40 sheet piles. Meanwhile, in a number of cases, due to organizational problems, it was somewhat lower.

A significant amount of work on vibration extraction of sheet piles was carried out at the Construction of the Gorky Hydroelectric Power Station in 1955 [42] and the Stalingrad Hydroelectric Power Station in 1957. Here, with the help of VPP-2 vibratory hammers, cellular sheet pile jumpers were dismantled. The lifting mechanisms were powerful Skoda crawler steam cranes, the maximum lifting capacity of which is 25 tons.

The work of removing sheet piles at these construction sites was carried out by two teams: one consisting of five people serviced the crane and the second, consisting of three people, serviced the vibratory hammer.

According to observations by workers of Gorkovgesstroy and the Research Institute, on average 11 minutes were spent on vibration extraction of one sheet pile at the base. The time spent on performing individual operations is given in Table 32.

| Name of Operations | Time in minutes |

| Lifting the vibratory driver with the crane boom turning | 0.7 |

| Installing the vibratory driver and affixing it to the pile. | 5.2 |

| Removing the sheet pile | 1.0 |

| Turning the crane boom to lay down the sheet pile | 0.7 |

| Laying the sheet pile and detaching the vibratory driver | 3.2 |

At Stalingradgidrostroy, great difficulties were encountered when extracting individual sheet piles, the finishing of which was carried out with air-steam hammers.

When dismantling the lintel, it was still possible to remove mainly the sheet pile, although most of the piles turned out to be severely deformed during finishing (Figure 87.) Characteristic types of deformation other than those shown in Figure 87 turned out to be bending of the bottom of the sheet pile due to an encounter with a boulder, rupture of the locks and the exit of the adjacent sheet pile, etc. All deformed piles were removed, as a rule, simultaneously with the adjacent undeformed pile. The individual piles were made up of two pieces without a strong joint between them. When extracted, their lower part came off and remained in the ground.

Experimental studies and production observations carried out by the authors show that with appropriate vibration parameters, when the amplitude of the vibration speed reaches 0.5-0.6 m/sec and there is a clearly defined breakdown of the pile from the ground, it is enough to extract it by applying a force only slightly more than the weight of the vibratory driver with a pile, and the extraction speed should not exceed 0.5-1 m/min.

Unfortunately, contrary to the instructions of the instructions [16], in production conditions the need to comply with the requirement for the speed of application of the extractive force is not always taken into account. When removing sheet piles, cranes are used where the hook lifting speed is 15-30 m/min. At this speed, the resistance to extracting the vibrating pile is very high, the cranes are overloaded, resulting in breakdowns of the cranes and vibratory drivers, ruptures of the sheet pile walls and other complications.

Of practical interest are the data given in Table 33.

| Type of Extraction Resistance | Force at the initial moment of extraction, tons | Time spent in removing the pile, seconds | Average extraction speed, m/min |

| Free-standing sheet pile | 6-8 | 35-45 | 20-25 |

| With resistance of one interlock | 8-10 | 45-55 | 15-20 |

| With resistance of two interlocks | 12-14 | 80-90 | 10-12 |

*According to N.A. Preobrazhenskaya,

From Table 33 it can be seen that in all cases the extraction was carried out with very high hook lifting speeds. As a result, the forces required for extraction always exceeded the permissible limits. If we take into account that the full compression load of the vibratory driver springs is 6 tons, then it becomes clear that in all cases, due to the high speed of application of the force, the springs were switched off from work, the intensity of vibration of the extracted pile was sharply reduced due to the involvement of the crane structures in the vibrations, as a result of which the efforts for extraction increased even more, reaching 10-14 tons. Naturally, with such efforts, there were breakages of springs, guide rods, caps and other parts of the vibratory driver, as well as ruptures of the walls of sheet piles above the hole, which were facilitated by errors made when cutting these holes.

During the first period of work on dismantling the longitudinal cellular lintel at the construction of the Stalingrad hydroelectric power station, no measures were taken to reduce the lifting speed of the crane hook. As a result, great efforts were required to remove the sheet pile with the ensuing consequences.

After the crane hook lifting speed was reduced to 4-5 m/min. work on extracting the sheet piles proceeded at a rapid pace and was then carried out without any particular difficulties, with the exception of those cases when there were individual sheet piles that were severely deformed during finishing with hammers.

It should be noted that similar omissions when organizing work on vibration extraction of metal sheet piles were made at the sites of the Gidrospetsfundamentstroy trust, Glavleningradstroy, etc. Due to the difficulties that arose during the extraction of sheet piles due to the high speed of lifting the hook, some experts made the conclusion that existing vibratory hammers are not suitable for sheet pile extraction. The experience of the Sevzapmorgidrostroy trust and other organizations has shown that such a conclusion is incorrect. Research and production experience of these organizations show that with proper organization of work, a metal sheet pile immersed in the soil of a vibratory pile driver can be successfully removed from there using a vibratory driver and appropriate power.

Let us move on to recommendations for the preparation and execution of work on vibration extraction of metal sheet piles from the ground when dismantling temporary fencing rows and structures. Note that during the construction and operation of temporary structures made of metal sheet piles, measures should be taken to prevent deformation of the locks of individual piles. The location and fastening of guide frames, spacers and other structural elements necessary for the construction and operation of the structure must be such that they can be easily removed when dismantling the structure and do not complicate the removal of sheet piles.

If, despite the measures taken, the locks of sheet piles have undergone significant deformations during hammering or operation of the walls, the possibility of using vibration to remove the sheet piles should be tested by experience.

Before removing the sheet pile, simultaneously with preparing the site and clearing it of objects that may interfere with the work, it is necessary to unload the sheet pile walls, that is, depending on the type of structure, remove the soil from the collapse prism, fill in the trenches fenced with the sheet pile, or remove the filling from the sheet pile cells, and in pressure structures, in addition, drain water. At the same time, all structural elements located on it must be removed from the plank, and the welding connecting the individual sheet piles must also be removed, in cases where there is one.

For vibrational flow of metal sheet piles, depending on their profile, length and weight, vibratory drivers V-100, VPP-2, VPP-4, VPP-5, VPP-6 can be used. The approximate purpose of each of the specified runway type machines is given in Table 34.

| Vibrator Size | Sheet Pile Profile | Maximum penetration into the ground, m | Limit Weight, kg |

| VPP-2 | Larssen III-V, ShK and ShP | 12-15 | 1500 |

| VPP-4 | Larssen III, ShK and ShP | 8-10 | 800 |

| VPP-5 | ShK and ShP | 6-7 | 400 |

| VPP-6 | ShK and ShP | 3.5-4 | 250 |

Vibratory drivers V-104 and V-108 are equipped with special shock absorbers that isolate the crane boom from vibrations. At Gorkovgesstroy, an attempt was made to use a vibratory driver type V-108 to remove sheet piles without a shock absorber. Strong vibrations were transmitted to the crane arm working with it, so the use of a vibratory driver without a shock absorber was prohibited by the boiler inspectorate.

To carry out work on extracting sheet piles using vibratory hammers, cranes (or pile drivers) are required, which mainly meet the same requirements as for sheet pile driving. The hook lift height should be such that the extracted sheet piles can be removed from the sockets of adjacent piles, and the lifting capacity of the cranes (or pile drivers) should be approximately twice the weight of the vibratory driver with the pile.

It should be emphasized again that the lifting speed of the crane hook (or piledriver) must necessarily be reduced to 4-5 m/min. It is highly desirable to equip the cranes used for vibration extraction of piles with load limiters, which would completely eliminate accidents with cranes and breakdowns of vibratory drivers due to overloads in cases where a sheet pile becomes jammed in the lock of an adjacent one.

The maximum force that can be applied to the suspension must correspond to the full compression load of the spring device of the vibratory driver (Table 35.)

| Vibrator Size | Compression Load, tons |

| VPP-2 | 6.0 |

| VPP-4 | 3.6 |

| VPP-5 | 2.7 |

| VPP-6 | 1.6 |

The load limiter is adjusted depending on the vibrator used.

All operations for extracting sheet piles using vibratory pile drivers are performed in the reverse order compared to immersion.

Removing the pile can be done in two ways. The first is that before turning on the vibrator, the crane operator creates a slight tension in the lifting cable, as a result of which the lower springs of the vibrator are compressed. Then turn on the vibratory driver and for 0.5-1 min. they vibrate without increasing the lifting force. After this time, the sheet pile is torn off the ground under the action of the elastic forces of the springs. Then the lifting force of the crane is gradually increased and the removal of the pile begins. The second method is that first, with the lifting cable in a free position, the vibratory driver is turned on. When the sheet pile, vibrating, sinks 2-4 cm into the ground, the piles begin to rise with an upward force applied. With this method, the detachment of the pile from the ground occurs under the influence of the own weight of the sheet pile and the vibratory driver. Therefore, it is enough to apply a force equal to double the weight of the vibratory driver with the pile so that the latter moves upward from the ground; in this case, the speed of movement should be approximately the same as when moving down. If the speed exceeds that which occurred during immersion, a correspondingly greater extraction force will be required.

Although the second method requires 1-2 minutes more time than the first one, it should be given preference. When removing a sheet pile immersed in the ground to a relatively shallow depth, the first method can be used.

Using any of these methods, you need to carefully monitor the condition of the lower springs of the vibrator. At those moments when, under the influence of traction force, the coils of the springs are completely closed, the lifting of the crane hook must be stopped. For some time, extraction occurs due to the elastic forces of the springs. After the springs have straightened, you can resume lifting the crane hook.

During the vibration extraction process, attention must be paid to the direction of the pulling force. In all cases, it is necessary to strive to ensure that this direction strictly coincides with the axis of the pile being extracted. This rule is especially important to observe in cases where, for some reason, it is necessary to remove sheet piles connected to the locks of two adjacent piles.

When removing the sheet pile with a crane, when the pile has left the neighboring lock, the sheet pile is transferred by turning to the installation site. First, lower the vibrator with the pile until it stops in the ground. Then, by simultaneously turning the boom and lowering the hook, the pile is placed on a stand on which the vibratory driver is detached.

In cases where the sheet pile is removed by a pile driver, the extracted pile is lowered simultaneously with its lower end being pulled by the cable of a winch installed for this purpose, or by the pile rope of a pile driver passed through a block fixed at a sufficient distance from the pile driver.

One thought on “Work on Vibratory Extraction of Metal Sheet Piles from the Ground”