For the rest of the book, click here.

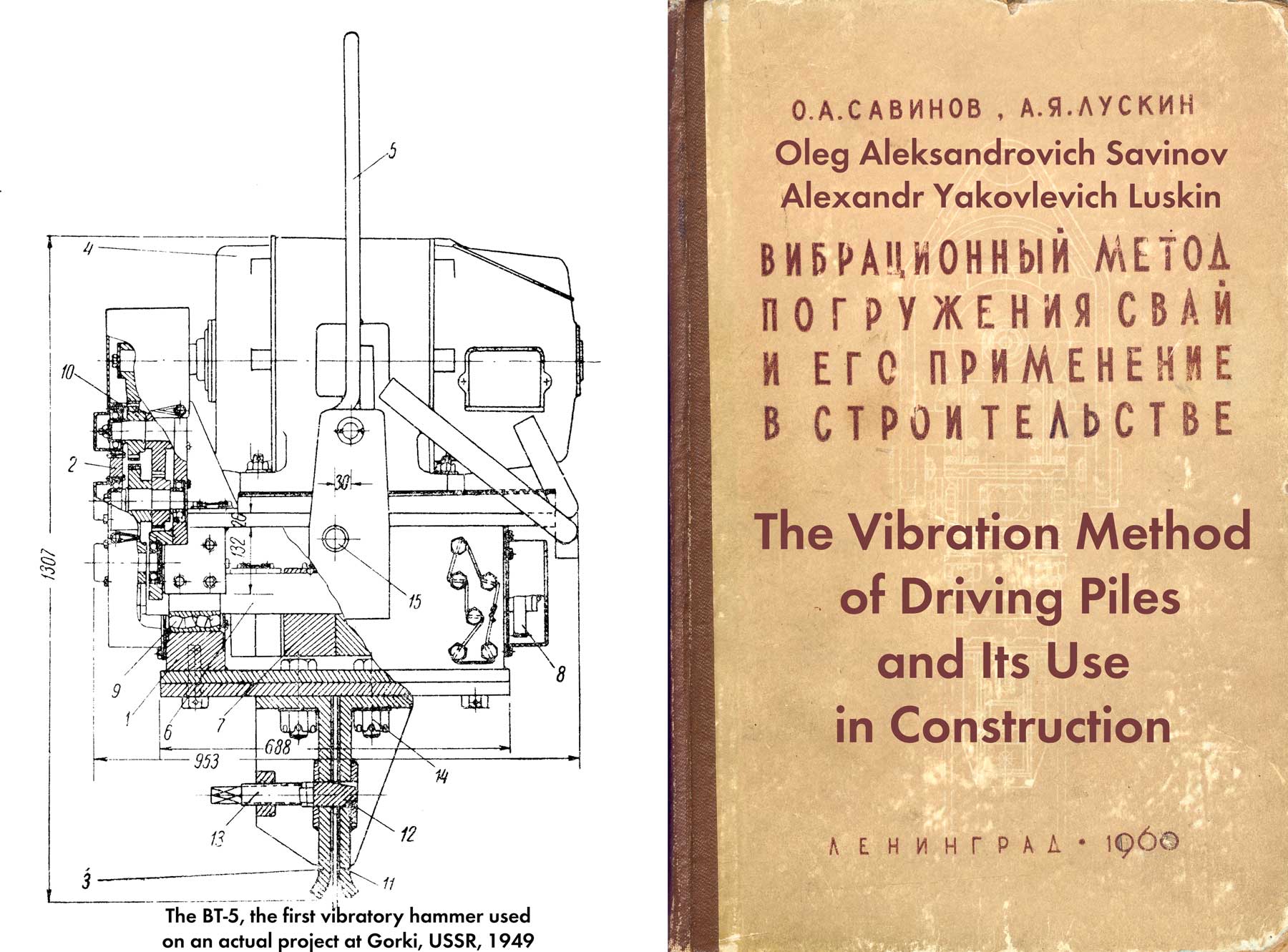

In a relatively short period of time that has passed since the time when the method of vibrating immersion of metal sheet piles was successfully applied for the first time in production conditions, the vibration and crane equipment used and the methods of work have changed radically.

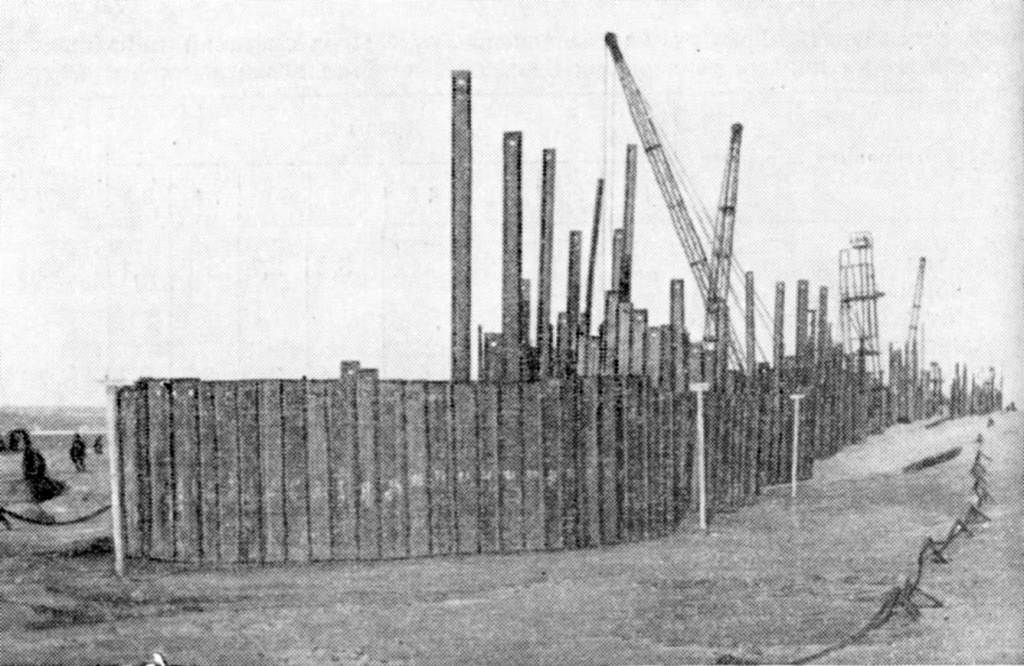

As is known, the first use of BT-5 vibratory hammers at Gorkovgesstroy made it possible to dramatically increase labor productivity at the construction of the bulkhead. Although the performance of auxiliary operations was not worked out and they were carried out manually and required a relatively long time, the average productivity using one crane was 20 piles per shift, and the highest 31 piles per shift. A total of 4,350 sheet piles were driven, of which 650 were driven by an air-steam hammer and 3,697 by vibratory pile drivers. The bulk of the work was carried out from December 1, 1949 to February 28, 1950. During this time, with the simultaneous operation of two tower cranes, 3,154 sheet piles were driven, which averaged over 1,000 piles per month.

Observations made by the regulatory research bureau of construction showed that when the sheet pile is driven by vibration, the productivity is almost two times higher than when driving with steam-driven hammers. The norms provided for the immersion of 20 piles per shift with vibratory pile drivers and 12 piles with air-steam hammers. It was also found that vibratory hammers consumed three times less electricity than air-steam hammers.

Saving. obtained as a result of the use of BT-5 type vibrohammers instead of air-steam hammers, according to the main types of costs (per 10 m of sheet pile immersion), according to V. E. Chubov [64] amounted to (see Table 27.)

| Types of Costs | Costs in Rubles | Savings | ||

| Impact Hammers | Vibratory Drivers | In Rubles | In Percent | |

| Wages of Workers | 225 | 121 | 104 | 46 |

| Depreciation Expenses | 273 | 120 | 153 | 56 |

| Electricity Costs | 157 | 53 | 104 | 73 |

At the construction of the Kakhovka hydroelectric complex [43], in addition to the BT-5 vibratory hammers used in the initial period, V-104 vibrating machines were used, and at the final stage of the work, VPP-2 vibratory hammers were also used.

At this construction site, with the use of vibration, a longitudinal cellular cofferdam of the excavation fencing, sheet pile fencing of the apron (gabion-type cells), upstream and downstream impervious walls under the drain dam were erected. For cellular structures sheet piling of the ShP-1 type was used, for impervious walls of the ShK-1 type. The length of the sheet pile, depending on the type of structure, ranged from 12 to 18 m.

The soils at the place of sheet pile driving are represented by fine-grained sands, in places with interlayers of dense clays 1-1.5 m thick, and separate lenses of coarse-grained sands with pebbles. In some places, at a depth of 8-10 m, limestone occurs.

Crawler cranes of the E-1003 and E-1004 types, equipped with a 28 m long boom, were mainly used as lifting mechanisms for vibrating the sheet pile. Only a part of the work on the longitudinal jumper was completed as well as at Gorkovgesstroy, with the help of tower cranes.

The presence of layers of dense soils in the soil complicated the process of plunging the sheet pile. Particular difficulties arose due to the fact that in the pit of the dam, the sheet pile had to be immersed in sands drained by deep water drawdown. Therefore, in some places it was necessary to apply vibrational immersion with preliminary washing/soil moistening, which generally gave positive results. In other places, where the preliminary destruction of the soil and its piling was not allowed due to the conditions of the structure, the sheet pile was finished with steam hammers.

The technology for the production of sheet pile driving at the construction of the Kakhovka hydroelectric complex was initially similar to that used at Gorkovgesstroy. Then it was improved. In particular, when VPP-2 vibratory hammers were used to drive the sheet pile, the need for braces disappeared.

It is interesting to compare the data on the productivity achieved in the indicated construction with different methods of sheet piling.

When constructing a temporary longitudinal bridge, the average capacity of one V-104 type pile driver was 20 piles per shift (200 m of sheet piles sunk into the ground), and the maximum was 28 piles per shift (280 m).

In the pit, during the construction of the sheet piling part of the apron, preliminary washing was carried out as follows. First, a pipe with a diameter of 100 mm with a hole in the tip of 15 mm was lifted by a crane, which, when water was supplied to the pipe at a pressure of 8-10 atm, under the action of its own weight, was immersed in the ground. Such washing was carried out in two or three places along the alignment of the wall. Then, with the help of the same crane, several sheet piles were immersed to the design depth. It took 1-2 minutes to drive a sheet pile to a depth of 10-12 m.

With such an organization of work, the productivity was 250–450 m of sheet pile immersed in the ground. In the course of sheet piling with an S-231 air-steam hammer (packages of two sheet piles), the productivity reached about 100, and on some days 130 m of sheet pile per shift.

It is interesting to note that in the initial period of construction, the teams performing sheet piling consisted of 11 workers, and after acquiring skills and mastering new methods of work, they consisted of 6, including a crane operator and a gas cutter.

In total, 19 thousand tons of metal sheet piles were driven during the construction of the Kakhovka hydroelectric complex, of which 9 thousand tons were driven into the longitudinal cellular cofferdam, and 5,500 tons into the apron fence.

At the construction of the Stalingrad hydroelectric power station, thanks to the use of a new type of vibratory driver and more advanced technology, it was possible to complete a huge amount of work in a relatively short time.

The temporary sheet piling of the excavation and spillway dam on Peschany Island, as well as the berthing facilities on the Green Island of the Stalingradskaya HPP, were also cellular structures. For their erection, a flat sheet pile of the ShP-1 type was used.

The soils on Peschany Island had the following strata from 0 to 8 m; from 8 to 12 m, medium-grained sands with an admixture of gravel and pebbles; from 12 to 13 m, a layer of pebbles, in some places wedging out; below 13 m, sandy-silty rocks, turning into sandstone at a depth of 16 m.

On Zeleny Island, in the berth construction area, medium-grained sands do not contain inclusions over the entire depth of sheet pile driving.

The protective bulkhead consisted of cylindrical cells of two types. The diameter of the cells of the longitudinal cofferdam was 10 m. The upper head included cells with a diameter of 16 m. Three cells were erected on Zeleny Island: two with a diameter of 5 m and one with a diameter of 20 m.

In a relatively short period of time, four types of vibratory hammers were manufactured and tested at the facility: BT-5, VP-50, V-l0 and VPP-2. Tests have shown that VPP-2 vibratory hammers are the most effective [33]. 26 vibrators of this type loaded 10,611 tons of sheet piles 14-18 m long in 8 months to a depth of 12-16 m.

Table 28 gives an idea of how the sheet pile was immersed by months.

| 1952 | 1953 | ||||||

| September | October | November | December | January | February | March | April |

| 120 | 283 | 625.4 | 1472.7 | 1901.7 | 2008.8 | 2543 | 1656.4 |

It can be seen from the table that most sheet piles were driven in the winter months.

During the construction of the cellular cofferdam, the in-line method of plunging the sheet pile was used. Each of the four streams was provided by an E-1003 type crawler crane with a 23 m boom, two VPP-2 vibratory pile drivers, a sector guide template, which was soon replaced by a T-37 type mine hoist, rigging and tools. The brigade consisted of 12 people; in the future, as the technology of work was mastered, it was reduced to five people. The brigade was headed by a crane operator, who simultaneously performed the functions of a copier operator.

Shortly after the start of work, the teams began to load 20-25 piles per shift instead of 13 according to the norm. Crane operator V. K. Ryleev achieved record productivity of 45 sheet piles per shift and crane operator V. G. Borisov, who drove 53 sheet piles per shift into the cell of the longitudinal cofferdam. These wonderful masters of their craft had all the sheet piles driven to the design mark, and had no deviations.

Of great interest are the data of numerous observations of the normative research station of Stalingradgidrostroy over the process of plunging the sheet piling (Table 29.)

| Operation | Cranes | Average Duration of Operation | |||||||

| 1st | 2nd | 3rd | 4th | 5th | 6th | 7th | 8th | ||

| Affixing vibratory driver to pile | 3.4 | 2.8 | 3.1 | 3.2 | 3.2 | 2.7 | 2.6 | 2.1 | 2.9 |

| Lifting the vibratory driving with the pile, driving it into the wall and lowering pile to target elevation | 3.81 | 2.6 | 2.9 | 2.6 | 2.4 | 2.6 | 2.3 | 2.2 | 2.7 |

| Detachment of the vibratory driver from the pile and movement to the net pile | 3.8 | 1.2 | 4.3 | 3.4 | 3.3 | 3.4 | 3.0 | 2.2 | 3.1 |

| Total | 14.5 | 9.6 | 14.1 | 13.4 | 12.9 | 12.7 | 10.7 | 8.8 | 12.1 |

The average productivity achieved in the area does not correspond to the time spent on the execution of individual operations. So, if one full cycle of work takes an average of 12 minutes, then about 40 sheet piles should be driven per shift. In reality, only 20-25 piles were driven. What caused it?

Separate piles could not be loaded by vibrators to the design levels, which sharply reduced productivity. From Figure 85 it can be seen that among the cells in which all the piles were sunk to the design marks, there were cells with sunk piles: shaped with sickle-shaped distortions formed during welding; ordinary sheet piles with locks damaged during transportation; wedge, and, finally, normal piles that encountered obstacles that could not be overcome with a vibrating driver. Most of these piles were finished off with air-steam hammers of the SM-9 and S-231 types, but at the cost of a lot of extra time.

So, if the speed of vibrational immersion of the sheet pile to a depth of 12-14 m was from 4.1 to 7.7 m/min, then when finishing individual sheet piles with hammers, it decreased from 2.7 to 1.4 m/h, i.e. more slowly about 180 times. Later, during the dismantling of the longitudinal bulkhead, it turned out that the obstacles encountered during the dive were so serious that the hammer blows mainly contributed to the deformation of the sheet pile, but not to its advance into the ground. The decrease in labor productivity was also affected by frequent failures of vibratory pile drivers at first. They were made without heat treatment of parts and equipped with electric motors not suitable for their electrical characteristics or mechanical strength.

Late delivery of sheet piling, oxygen and other materials, poor site and equipment preparation, etc. also affected labor productivity.

Despite all these reasons, which slowed down the pace of work on the construction of the longitudinal cofferdam and the upper head, the actual output far exceeded that stipulated by the norms for driving sheet piles with impact hammers. Thanks to this, the entire scope of work was completed on time before the onset of spring floods. The total savings on these facilities at the Stalingrad hydroelectric power station amounted to over 1.5 million rubles.

The installation of a 13 m long Larssen V-type metal sheet pile into the base of the spillway dam of shipping locks and trash-retaining structures at this construction site took place under more difficult conditions. At a depth of 6-10 m from the bottom of the pit, there were layers of dense clay, pebbles and sandy-silty rocks, and at a depth of 10-11 m, sandstone of various strengths.

Although such foundation soils are beyond the effective application of the vibration driving method, it was still decided to plunge the sheet pile to a certain depth by vibration, and then finish them off with air-steam hammers.

Up to a depth of 6-8 m, this operation was successfully carried out with a VPP-2 vibratory hammer. Finishing with hammers turned out to be a laborious and long process. In connection with this, it was decided to simultaneously use vibration and air-steam equipment, which fully justified itself; increased labor productivity, decreased the cost of sheet piling.

During the construction of the Kuibyshev hydroelectric power plant [36], due to severe soil conditions, out of 45 thousand tons of sheet pile driven into the ground, about 2500 m were sunk by vibratory drivers. Here, a combined method was partially used – a preliminary set of sheet pile walls with vibratory drivers, followed by refinishing with hammers. However, it did not always give positive results. In particular, during vibrational immersion in sandy foundations drained by deep water drawdown, the soil is strongly compacted, which made it difficult to finish the sheet pile with hammers.

Vibratory immersion of sheet piling types ShK-1 and ShK-A 11-12 m long into water-saturated soils at Kuibyshevgidrostroy did not cause any difficulties and was successfully carried out with the help of cranes and pile drivers.

Vast experience in the use of vibrators has been accumulated by the Leningrad Department of the Sevzammorgidrostroy trust [45]. At many objects, metal sheet piles were driven by vibration with the help of floating and land pilers. At the same time, on average, 16-18 piles were driven per shift, which is 1.5-2 times higher than the productivity of air-steam hammers in similar conditions.

There was a case when a Larssen III type sheet piling 14 m long worked to a depth of 10 m with VPP-2 vibratory pile drivers in combination with a floating headframe. A team of four people completed the entire cycle of driving one pile in an average of 30 minutes. (See Table 30.)

| Operation | Time in Minutes |

| Moving Crane | 4.7 |

| Opening Clamping Mechanism | 4.4 |

| Affixing Vibrator to Pile | 5.0 |

| Lifting vibratory driver and pile and driving a pile into the neighboring interlock | 7.0 |

| Further Pile Driving | 2.5 |

| Uncoupling the Vibrator | 3.9 |

| Other Related Work | 2.5 |

When using caterpillar type cranes E-505, E-650 or K-102, K-252 on a truck, the time spent was less, and the productivity was correspondingly higher than when working with pile drivers.

In the very first year, thanks to the use of vibratory hammers, the Leningrad department of the trust Sevzapmsrgidrostroy received savings of about 450 thousand rubles.

The vibromethod of plunging a metal sheet pile has been successfully used and continues to be used by many organizations.

Let us dwell briefly on the example of using the vibration method of immersion and extraction of a metal sheet pile in trench work by one of the trusts of Glavleningradstroy [40].

Starting from 1957, in the trenching work carried out by the organizations of this trust, a metal sheet pile of the ShK-1 type 6-7 m long, immersed in the ground and extracted from the ground with VPP-5 vibrators (Figure 86.) is widely used for trench fastening. Cranes of type E-505 and K-51 are used as a lifting device. The work is carried out by a team of four people, including a crane operator.

The vibration method ensured the comprehensive mechanization of all work, made it possible to completely switch over to excavating the soil from the trench with excavators, to repeatedly use inventory metal sheet piles instead of wooden ones, to significantly increase labor productivity and reduce the cost of work.

In most cases, a sheet pile 6-7 m long is immersed in the ground in 1-1.5 minutes of vibrator work. The total time spent on the entire cycle averages about 10 minutes. The same amount of time is spent on the extraction of one pile.

A team of workers drives or excavates 45-50 sheet piles per shift, which is a high figure. In difficult conditions, in the presence of soils composed of dense dry sands, which required the use of their preliminary moistening, about 30-35 sheet piles were driven per shift.

The positive experience of vibratory immersion and extraction of inventory sheet piles in deep trenches prompted Glavleningradstroy to use, instead of wooden sheet piles, a standard metal sheet pile up to 5 m long when laying pipelines in trenches of shallow depth (2-3 m).

One thought on “Basic data of production experience and technical and economic indicators of vibration immersion of metal sheet pile”