Editor’s Note: the term “pile drivers” or “piling headframes” means what we would call today a dedicated rig. Before the advent of crane lifted and controlled pile driving, people would use a specialty mast type of arrangement–skid or turntable mounted–to drive piling, dragging it from one pile to the next. The arrangements shown here are a little more sophisticated than that but not much. Vulcan used the term “pile driver” to designate a complete rig, and some of these rigs can be seen in our post In the Catalogue: Vulcan Leaders, Rigs and Accessories, 1906-1931.

If at the construction site there are no cranes of the required lifting capacity and lifting height of the hooks, but there are pile pile drivers that meet these requirements, then these headframes can be used to drive sheet piles with vibratory drivers.

It is not as convenient to load sheet piles with vibratory pile drivers using pile drivers as with cranes, due to the low maneuverability of pile drivers. Nevertheless, when using universal pile drivers with a vibro-loader, the acceleration of work compared to driving with hammers is achieved not only due to a decrease in the net time for driving a pile into the ground, but also due to more advanced technical characteristics of auxiliary operations.

For vibratory immersion of a sheet pile, usually a tower (of the “Fundamentstroy” type), universal land and floating pile drivers are used in straight walls. The use of pile drivers for the construction of cellular structures from sheet piling is associated with great difficulties and cannot be recommended.

It is known that the truss of land-based universal headframes can lean forward without loss of stability. Therefore, it is recommended to drive sheet piles with vibratory drivers when the truss is tilted. In this case, the rails along which the pile driver moves along the wall are removed by a distance corresponding to the reach of the lifting cable hook. The work is carried out basically in the same way as with a jib crane, with the fact that the sheet pile is fed directly to the pile driver and placed near the rail track.

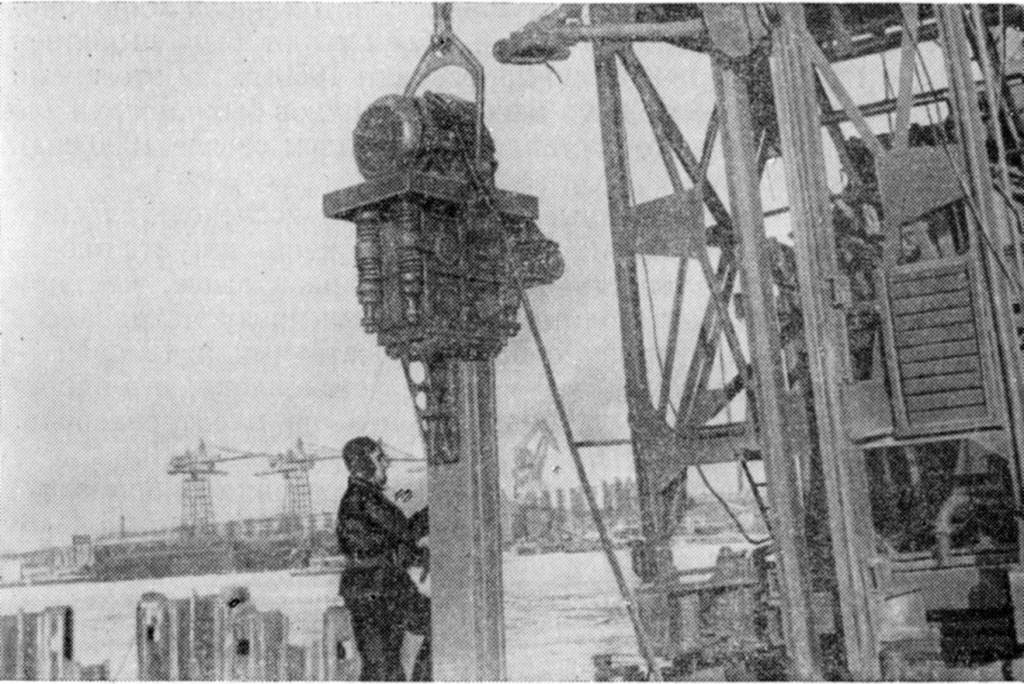

An approximate diagram of the organization of work on driving a sheet pile with a VPP-2 vibratory driver using a universal pile driver is shown in Figure 83. In this case, pulling the sheet pile to the pile driver and laying it for capture by the vibratory driver is carried out by an auxiliary crane or a pile cable of the pile driver.

When plunging a sheet pile with vibratory drivers from conventional tower pile drivers, the body of which cannot tilt forward, work is carried out similarly to the scheme of driving a sheet pile with impact hammers.

When the vibratory driver, not connected to the guide booms of the pile driver, is raised to the upper position, the sheet pile is lifted with a pile cable and brought into the lock of the previously loaded one. Without releasing the pile cable, the vibratory driver is lowered onto the pile head and the wedge is inserted into the pile hole, fastening it to the vibrator head. These operations are usually carried out by two workers located on the side platforms of the pile driver at the level of the pile head.

After fastening with a vibratory driver, the pile cable is removed from the pile and the immersion begins. In this case, it is recommended to slow down the lifting cable drum somewhat so that the pile is plunged into the ground strictly vertically, without deviations.

Based on the experience, in order to prevent the formation of fan-shaped deviations and “blockages” of the wall onto or away from the impact driver, the following conditions should be observed: the rails on which the impact driver moves must be laid so that the axis of the neck of the head of the suspended vibratory driver approximately coincides with the axis of the wall; the position of the pile driver before driving the pile should be such that the axis of the pile being driven into the lock of the neighboring one, which was previously loaded, was strictly vertical.

In cases where, nevertheless, for some reason, rolling deviations occur, it is necessary to take measures to prevent and correct deviations, similar to those indicated in the previous paragraph.

The driving of sheet piles with the help of floating pile drivers or cranes in water areas is carried out basically in the same way as on land (Figure 84). The design of guide devices, as well as the conditions for delivering the sheet pile to the place of immersion and the organization of the process of capturing, fastening and lifting the pile, must take into account the presence of unrest. Usually, the vibratory immersion of a sheet pile in open water areas with the help of floating pile drivers or cranes is performed with waves not exceeding one point.

One thought on “Features of the Technology of Vibratory Immersion of Sheet Piling Using Piling Headframes”