For the rest of the book, click here.

Editor’s note: this is the beginning of the section concerning the application of vibratory drivers to sheet piles. One problem described here was keeping the sheets in alignment and now allowing them to get out of alignment (the “fan” effect described in below) which only gets progressively worse as you drive down the wall. Here the names of the two crane operators who figured out how to avoid this are mentioned; it is a rare tribute to the construction workers who turn engineering designs into reality and make equipment work.

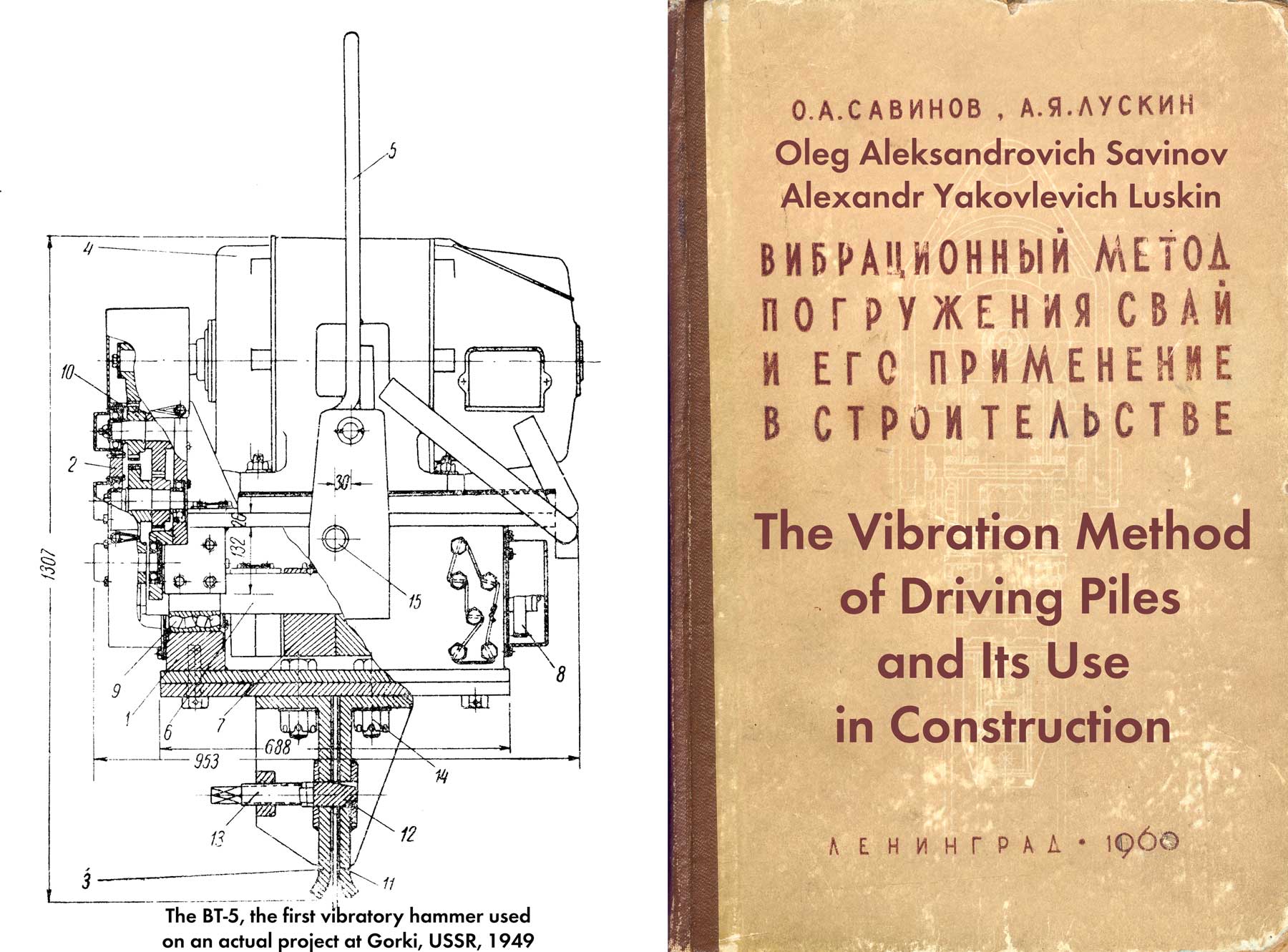

Until recently, metal sheet piles were hammered into the ground in most cases with air-steam, diesel and mechanical hammers; the vibrational method of immersion and extraction of the sheet pile began to be used only in 1949. However, since then it has become widespread. To date, more than 170,000 tons of metal sheet piles have been sunk into the ground by vibratory hammers, of which about 100,000 tons are used in the construction of hydroelectric power plants.

As studies and accumulated production experience show, the area of effective application of the vibration immersion method when using existing types of vibratory drivers is limited mainly to water-saturated sandy and plastic clay soils. The presence of pebble or dense clay layers of small thickness (up to 1-1.5 m) does not prevent the successful use of vibratory drivers. If there are dry sands, dense clays, thick pebble layers, rocky and other high-strength soils at the base of the structure, the efficiency of using vibratory hammers is sharply reduced, and in some cases the possibility of their use is completely excluded. Therefore, it is not recommended to use these machines when thick layers of dense clays, gravel-pebble soils or rocks lie at the base of the structure. In these cases, preference must be given to air-steam hammers.

In dry sandy soils, vibratory hammers can be effectively used in combination with pre-washing: in clayey soils, it is sometimes more useful to use electroosmosis.

It is not uncommon for the upper layers of the soil into which the sheet pile must be immersed consist of water-saturated sands, loam or weak clays, and below – dense clays or pebbles.

Under these conditions, the expediency of using vibration machines for driving sheet piles must be verified by experience.

It is advisable in some cases to use a combined method: to immerse the sheet pile by vibrating, and then to finish it with air-steam hammers to the design depth. This method was used at the Kuibyshevgidrostroy, Stalingradgidrostroy and at the construction of the Kakhovskaya hydroelectric power station.

Depending on the soil conditions, vibratory hammers can be used for the construction of temporary and permanent structures from metal sheet piles on land and in water areas.

In contrast to air-steam hammers, vibratory hammers are designed for conducting: works by sequentially immersing each sheet pile to the required (design) depth.

As experience shows, with the correct organization of work and the availability of trained workers, the quality of sheet piling, performed by the method of vibratory successive piling to full depth, can be no worse than when driving with hammers of a pre-set row.

During vibration immersion of the sheet pile in some areas of work at Stalingradgidrostroy, fan-shaped deviations of the top of the sheet pile in the direction of driving, i.e., “stealing” of the top of the sheet pile, were found, and in others – fan-shaped deviations of the bottom of the sheet pile also in the direction of driving. The study showed that when the sheet pile was immersed with a VPP-2 vibratory pile driver, the “hijacking” of the top or bottom of the sheet pile arose mainly as a result of the unsatisfactory organization of the work of the crane operator and the team engaged in immersing the sheet pile. Having mastered the method of vibration immersion, crane operators V. G. Borisov and V. K. Ryleev subsequently achieved the complete elimination of fan deviations.

The sheet pile of the impervious curtains in the pit of the spillway dam was plunged under difficult geological conditions. By taking appropriate measures, it was possible to reduce the fan: nye deviations to a minimum. One wedge pile was used through 500-600 sheet piles.

The most important feature of the vibration driving method, which significantly distinguishes it from the impact one, is the need for a rigid fastening of the driven pile with the vibratory driver. This feature determined the birth of a new technology of work, which is based on the operation of fastening a sheet pile located in a horizontal position at ground level or on special scaffolds, and the simultaneous lifting of a vibratory driver with a sheet pile. For these purposes, jib cranes on caterpillar, automobile or railway tracks are used, less often – tower cranes. However, it is not uncommon for pile drivers to be driven by vibration machines, which, in combination with vibratory pile drivers, in the presence of appropriate soil conditions, as a rule, provide higher productivity than in combination with air-steam hammers.

One thought on “Manufacture of works on vibration immersion and extraction of metal sheet piling: General Information”